Win The Shift

Overview

Many operators don’t know what the target is for their shift, or if they’re currently on-track to hit that target. They start their shift not knowing what a ‘win’ is, and leave at the end of the shift not knowing if they ‘won’ or ‘lost’. Not only do we all like to go home knowing that we ‘won’ today, but if you set a target then your team is much more likely to hit it!

A simple test: Go out to the factory floor. Find an operator. And ask two simple questions:

- “What is your target for this shift?”

- “How far ahead or behind this target are you, right now?”

If your operator can’t quickly and accurately provide this information, you have an opportunity to help them win their shift today. When your teams are regularly winning their shift, you will consistently win the week, month, and quarter.

This page provides a simple and effective way to help you set and beat your production targets.

Plan to Win

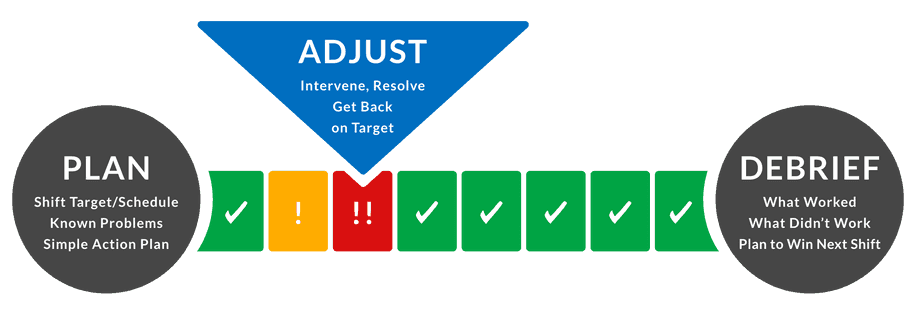

Your favorite teams don't win games by accident. Before each game, they create a plan. The plan has contingencies if the play goes off-track. Then they execute the plan, and adjust the play as they go. The manufacturing version of this strategy is:

Plan

Start the shift with a quick (maximum 5 minute) stand-up meeting with the operators to:

- Agree on the shift target. Be specific. (e.g., pieces, pallets, pounds, packets, etc.)

- Identify known potential issues. (e.g., changeovers, material changes, operator needing training.)

- Identify any open problems from the last shift. (e.g., unresolved breakdowns, material issues.)

- Agree on a simple action plan so that people know what to focus on, when to call for help, and who to call if they fall behind.

Adjust

Track production in real-time. If the team falls too far behind their target, intervene quickly to help them get back on track. This might involve:

- Allocating engineering resources to a machine that’s having technical issues.

- Carrying out some on-the-job training if an operator is struggling.

- Resolving material issues that are causing running problems.

- Rebalancing the allocation of operators across machines.

For a more robust approach, consider implementing a Short Interval Control process. Short Interval Control is a structured process for reviewing production every 2 or 4 hours to identify a small number of improvement actions.

Debrief

Many teams miss this important step and miss valuable information as a result. At the end of the shift – gather the team for a quick debrief. Capture what worked and what didn’t.

- Did the team hit their shift target?

- If they did, what should be repeated on the next shift (and briefed to people on other shifts)?

- If they didn’t hit their shift target, what should be done differently for the next shift?

Publish these actions in the team area and use them in your next Plan-to-Win session.

Track Production in Real Time

The biggest challenge that most teams face is – how do we accurately track production vs. the target?

Manual Data Capture

The traditional approach to monitoring production is to use an hour-by-hour whiteboard. Hour-by-hour or ‘Production Control’ boards are heavily featured in the Toyota Production System (TPS) as a way of visually managing production and particularly to balance the schedule and manage production flow.

A typical hourly production board tracks the required hourly target and an accumulated hourly target and compares these targets to the actual production and an accumulation of production for the entire shift.

There are three big challenges with hour-by-hour production boards:

- Updates: If someone doesn’t manually update the board, the data is immediately out of date.

- Accuracy: If you run products at different speeds, it is hard to set a real target. Many teams use a target based on an average rate—that doesn’t create a true target.

- History: Once the board is cleaned…the data is gone forever!

Automated Data Capture

Two great benefits from tracking production with an automated monitoring system is that it will be accurate (tracking products by part) and that it will provide real-time feedback (either on the machine with a visual display, or on a computer as a dashboard).

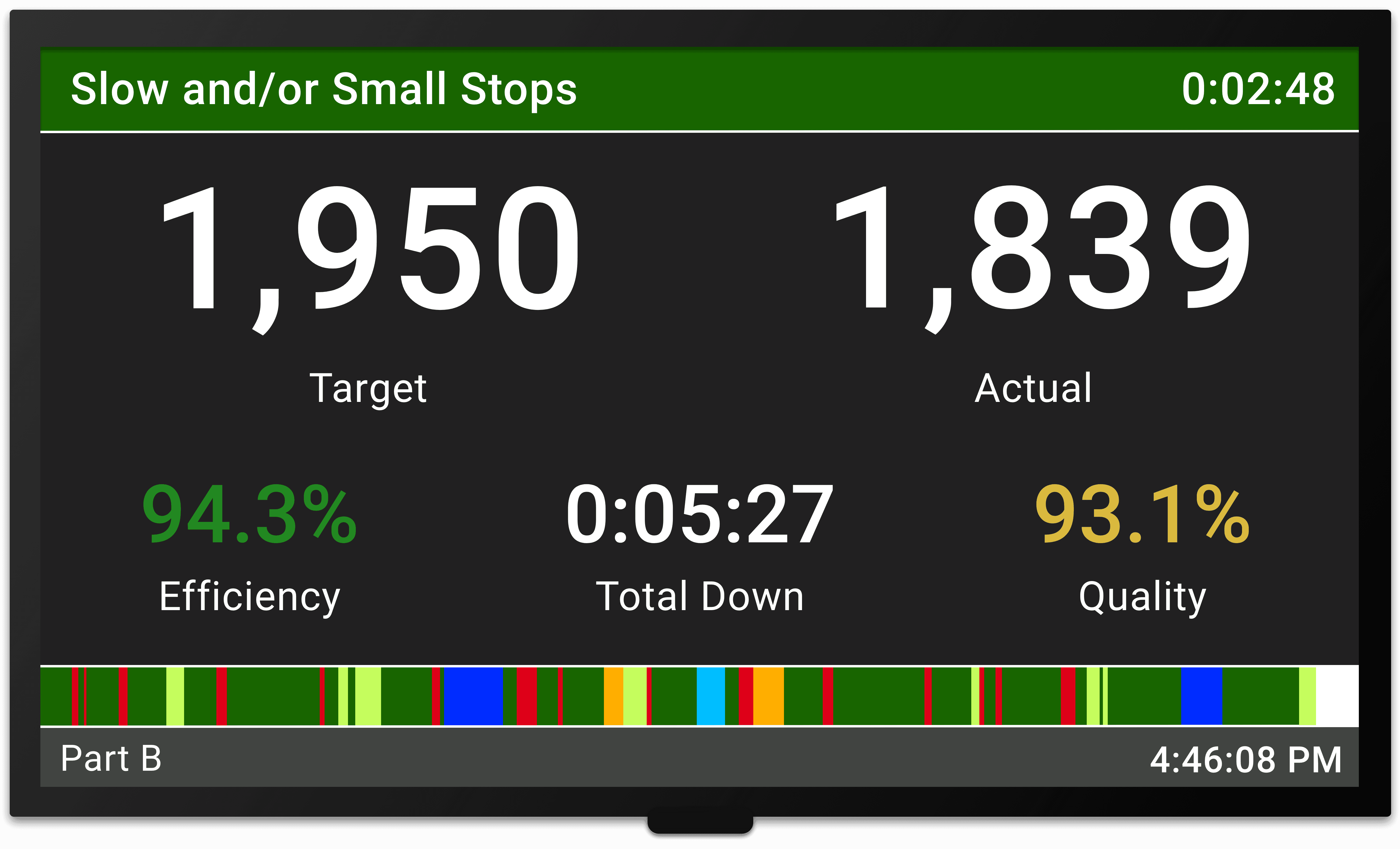

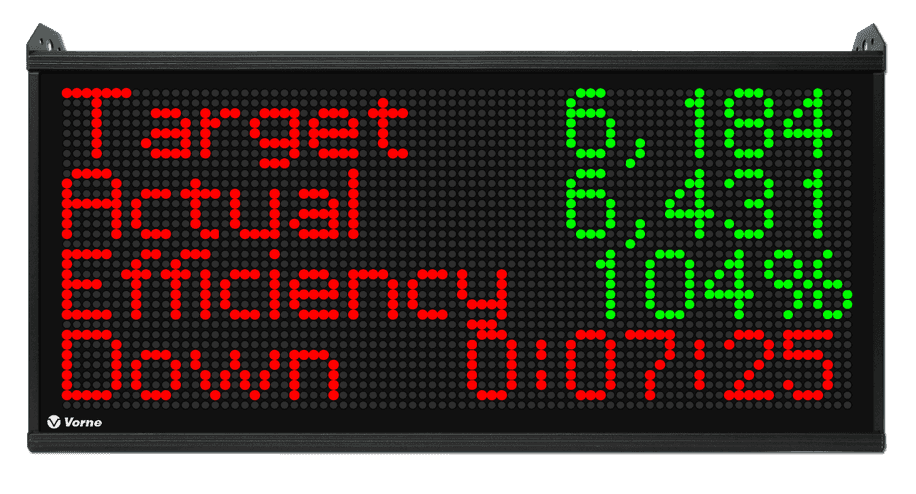

We find that the best way to track production in real-time is to use a combination of metrics that we call “TAED”: Target, Actual, Efficiency, Downtime. These are:

- Target: Real-time count of good parts that should have been manufactured.

- Actual: Real-time count of good parts that actually were manufactured.

- Efficiency: Ratio of actual good parts to target good parts.

- Downtime: Downtime for most companies is the largest loss and a component of OEE Availability.

By comparing Target to Actual, your team can pace production in real time. They are winning the shift when the Efficiency is at 100% or more. At the end of the shift, the display could then provide instant feedback telling the team that they’ve beaten the target:

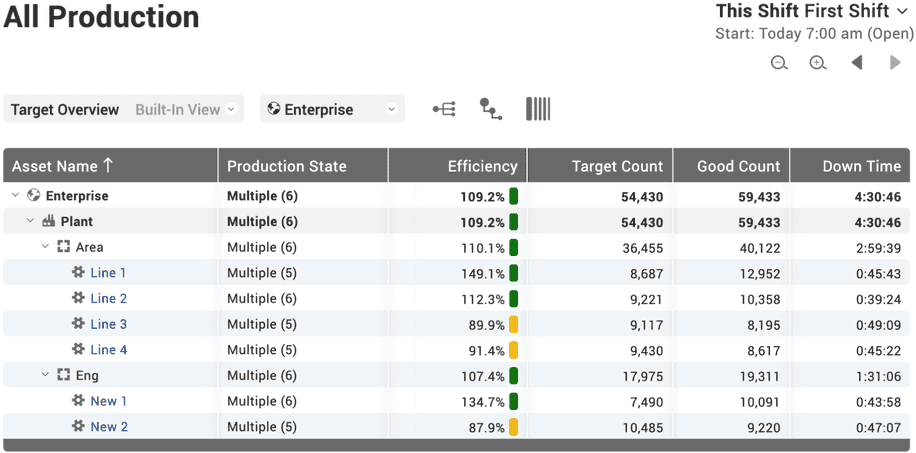

If you have multiple machines or processes, an automated system can provide a real-time dashboard for every machine. This will help your managers to allocate resources across the production floor to ensure that every team can win their shift.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.