FAQ

Introduction

Have a question?

Feel free to give us a call.

Want to reuse content from this website?

The content on this site is registered with the US Copyright Office. To learn more, read our policy on reusing content.

Getting Started

How should I get started with lean manufacturing?

A good place to start your lean manufacturing journey is with TPM, OEE and the Six Big Losses.

- TPM: Getting operators involved in maintaining their own equipment, and emphasizing proactive and preventive maintenance will lay a foundation for improved production with fewer breakdowns, stops, and defects.

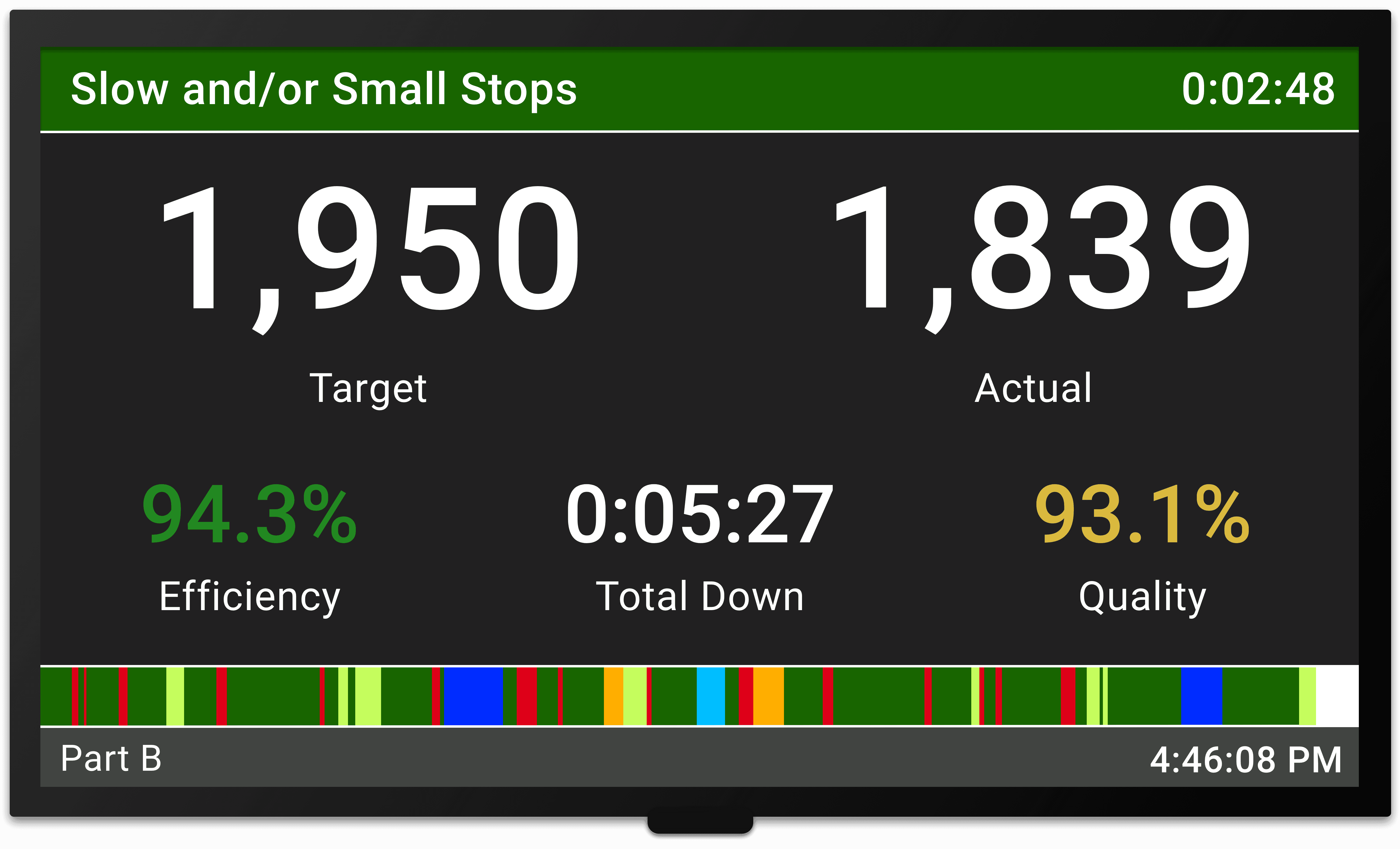

- OEE: OEE measures how close you are to perfect production (manufacturing only good parts, as fast as possible, with no downtime). It is a great metric for benchmarking progress in improving manufacturing productivity (i.e., eliminating waste).

- Six Big Losses: One of the major goals of TPM and OEE programs is to reduce and/or eliminate what are called the Six Big Losses – the most common causes of equipment-based productivity loss in manufacturing. The Six Big Losses traditionally are categorized as Equipment Failure, Setup and Adjustments, Idling and Minor Stops, Reduced Speed, Process Defects and Reduced Yield. An alternate way of categorizing them is Unplanned Stops, Planned Stops, Small Stops, Slow Cycles, Production Rejects, and Startup Rejects.

Seiichi Nakajima published a book in 1984 called TPM Nyūmon (published in English as Introduction to TPM: Total Productive Maintenance), which we highly recommend as an as an excellent and practical introduction to TPM, OEE and the Six Big Losses.

Theory of Constraints

Where should we focus our improvement efforts?

A common problem in manufacturing improvement programs is deciding where to focus resources. Should all equipment be improved? Should the improvement focus be on Downtime? Setup? Slow Cycles? Small Stops? Quality?

A related question is where to measure OEE (Overall Equipment Effectiveness). At every step? At the end of the line? At the beginning of the line?

The answer to both sets of questions is the same – focus on the manufacturing constraint (the bottleneck).

The concept of “the constraint” was introduced by Eli Goldratt in his 1984 novel The Goal. Dr. Goldratt described how every complex system, including manufacturing processes, consists of multiple linked activities, one of which acts as a constraint upon the entire system. The constraint should be improved until it no longer limits production, at which point the next constraint should be identified. Over time, Dr. Goldratt developed these concepts into a comprehensive set of tools known as the Theory of Constraints.

Bottom line – measure OEE AND focus improvement efforts on the constraint. The constraint is the fulcrum (i.e., point of leverage) for the entire process. Focusing improvement efforts on the constraint ensures optimal use of resources and is the fastest route to improved productivity and profitability.

How do reject parts affect OEE in a multistep manufacturing process?

The first thing to consider in a multistep manufacturing process is that OEE should always be measured at the constraint. In this context, OEE is a measure of productive time at the constraint, and OEE Quality Loss is a measure of time lost at the constraint because a part has not been made correctly the first time. Consider the following scenarios:

- A part is rejected BEFORE the constraint but DOES NOT slow or stop the constraint (because there is excess capacity before the constraint). From the perspective of the constraint there is no OEE Loss.

- A part is rejected BEFORE the constraint and DOES slow or stop the constraint (because there is not enough capacity before the constraint to cover the lost time). From the perspective of the constraint there is no OEE Quality Loss because the constraint has not yet processed the part, however, there is an OEE Performance Loss or OEE Availability Loss (because the constraint is momentarily STARVED).

- A part is rejected AT the constraint, which DOES affect the constraint (because the constraint must produce an additional part). From the perspective of the constraint there is an “internal” OEE Quality Loss.

- A part is rejected AFTER the constraint, which DOES affect the constraint (because the constraint must produce an additional part). From the perspective of the constraint there is an “external” OEE Quality Loss.

In addition to OEE Loss, you may have Labor Loss (if a reject part is reworked) or Yield Loss (if a reject part is scrapped). Note that Yield is a measure of the conversion of “material in” versus “good product material out”. Labor Loss and Yield Loss can occur at any point of the manufacturing process, and are independent of OEE Loss.

Beware of the temptation to measure “everything” when you actually just need to measure “enough” to drive improvement and to capture significant costs. Most companies spend too much time measuring and too little time using the information they gather.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.