Short Interval Control (SIC)

What Is Short Interval Control?

Short Interval Control (SIC) is a structured process for identifying and acting on opportunities to improve the effectiveness and efficiency of production. It is a factory-floor process that engages team members to review performance data three or four times within their shift to assess where they need to focus their efforts to improve performance.

SIC can be described as a type of Kaizen process as it encourages teams to work together to achieve regular, incremental improvements to the manufacturing process.

A key feature of SIC is the use of real-time production data to guide instantaneous front-line decision-making. Teams are trained to collect, analyze, and react to this data to drive significant performance improvement from the factory floor. In our experience, manufacturing processes can make significant improvements in OEE (Overall Equipment Effectiveness) when effectively implementing SIC (e.g., a site with 60% OEE improving to 65% OEE in under three months and to 75% OEE within two years).

Benefits of SIC

A successful implementation of SIC will have the following benefits:

- Increased OEE by focusing on immediate and relevant losses within the shift

- Increased effectiveness by utilizing high-quality data at its source to drive decision making

- Fast-pace improvement localized focus increases the pace of improvements

- Improved employee engagement teams gain significant control over how the line is run

Basics of SIC

Core Concept

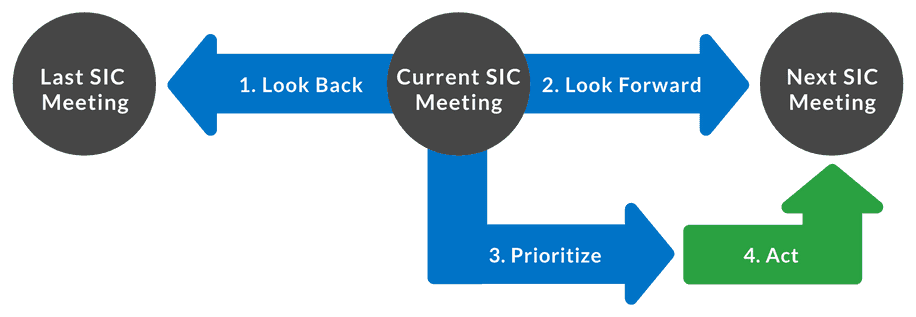

The core principle behind Short Interval Control (SIC) is very simple: we cannot change the past; however, we can learn from it to improve the future. At a practical level, SIC is implemented as a series of short (five to ten minute), focused line-based reviews, carried out every two to four hours by front-line teams to review losses and to identify actions that will improve performance in the future.

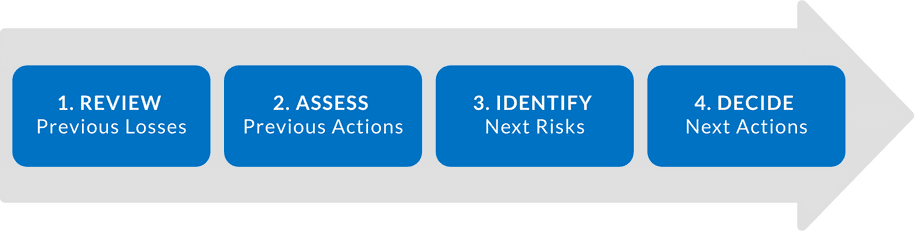

An effective SIC process is all about repeated cycles of identifying and then implementing effective actions to improve performance. To achieve this goal, during each SIC review the team completes a series of four steps:

Looking Back to the Just-Completed Interval

- Review Previous Losses: evaluate the top losses for potential countermeasures

- Assess Previous Actions: evaluate their effectiveness and whether follow-on actions are needed

Looking Ahead to the Next Interval

- Identify Risks: identify upcoming conditions and changes that may adversely affect performance

- Decide Actions: decide on a specific set of actions to be completed during the next interval

The actions decided upon during the SIC review are then carried out by the team to maximize production during their shift.

Key Elements of Short Interval Control

Key conditions for a successful Short Interval Control (SIC) process are:

- A team that has the skills and the desire to make improvements to the production process

- Leadership that supports and drives the SIC process (through words and actions)

- High quality data that accurately identifies all significant losses (both reasons and durations)

- Forms that capture results from the last interval and actions for the next interval

Documenting the SIC review is essential to achieving a sustainable process. First, creating a written plan helps the teams to commit to their actions, especially if the documentation is displayed visually in the work area. Second, the document can be used to support shift handovers. Third, the documentation can be reviewed and audited for training and coaching opportunities.

Many teams first document their SIC reviews on paper forms, and gradually implement intranet-based tracking spreadsheets or database systems to record performance, losses, and the actions taken to resolve specific losses.

Using Data to Drive SIC

The Role of High-Quality Data

High-quality data is absolutely essential for an effective Short Interval Control (SIC) process, especially since the actions taken are directly triggered by the data. Best practices are:

- Automatic data collection is preferred (as it is more accurate)

- Tabular information is best for capturing the current state

- Trended information is best for gaining historical perspective

- Data must reflect the SIC review period (shift-based data does not have sufficient granularity)

- Data must accurately identify all significant forms of loss (reference the Six Big Losses)

- Real-time data is strongly preferred (to tighten the “action-to-results” feedback loop)

When working with poor quality data the worst case scenario is that the team will spend their time reviewing the wrong losses, identifying the wrong actions, and potentially may make performance worse. Even in a best case scenario the team will spend an unnecessary amount of time processing, collating, and verifying data before getting into the value-added part of the SIC review – identifying actions.

Manual vs. Automatic Data

Either manual or automated data collection can be used to drive the SIC process. Manual data collection is most effective in the early stages as it provides a first-hand connection between actions (by team members) and results (improved performance). On the other hand, there are numerous and compelling benefits to automated data collection:

Accuracy

Based on real-world experience across a broad spectrum of companies, manual systems significantly understate downtime (typically by 20% to 40%). With automatic run/down detection, downtime accuracy can approach 100%.

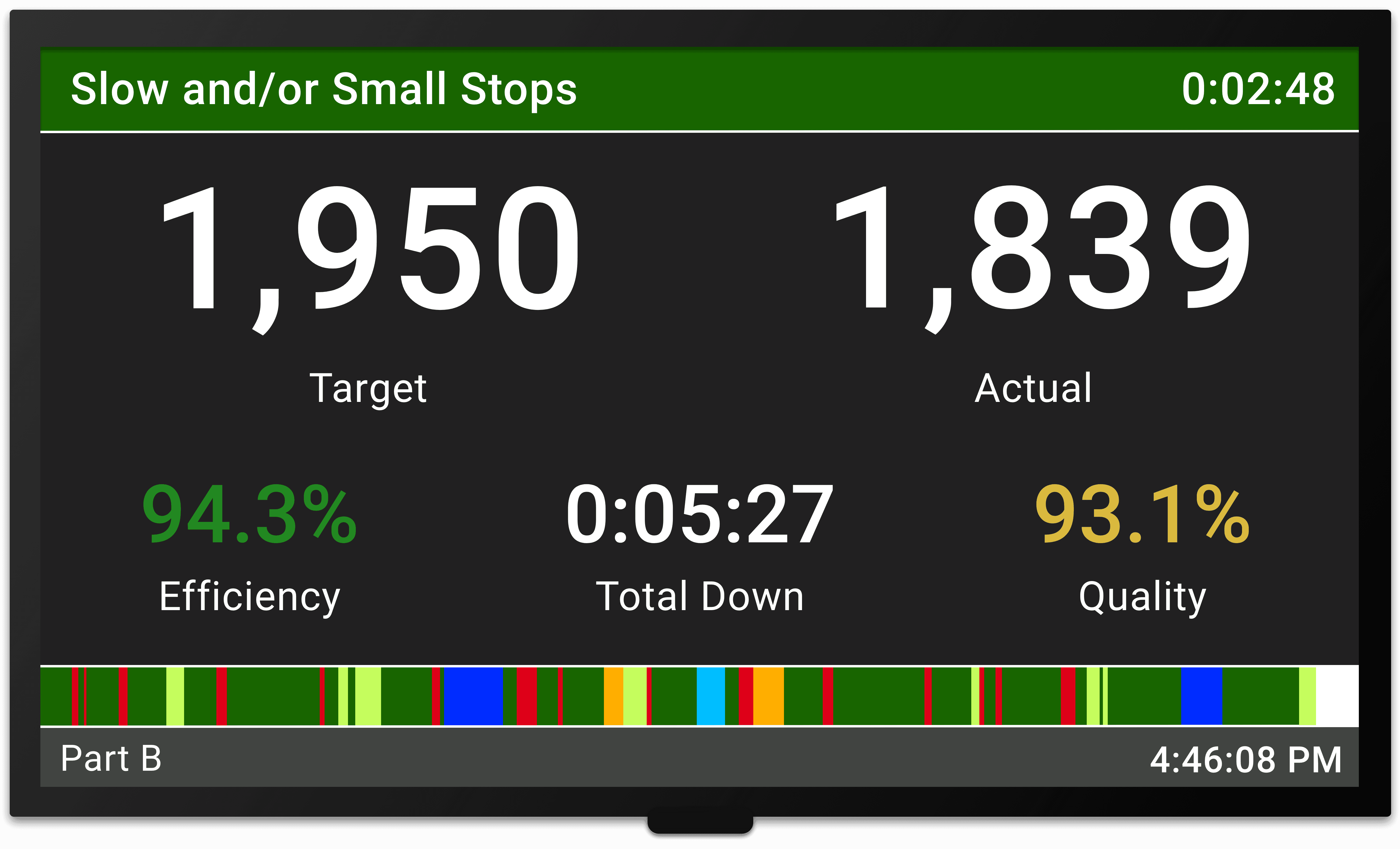

Small Stops and Slow Cycles

For most equipment, it is impossible to manually track small stops and slow cycles. This means that a great deal of potentially useful information about run-time behavior is simply lost.

Less Paperwork

With automated data collection, the operator spends less time on paperwork and more time focused directly on the equipment (less time collecting data and more time acting on it).

Real-Time Data

Automated data collection provides results in real-time, enabling faster response and better control over the improvement process.

Conducting SIC Review Meetings

Best Practices for Short Interval Control Review Meetings

The Short Interval Control (SIC) process is driven by SIC review meetings, which are quick, highly focused, and time-boxed (they are intense bursts of focused energy). The focus of these meetings is on one thing – developing a set of actions that will rapidly improve production.

Some best practices for SIC review meetings are:

- A focused team of three or four people (lead operator, maintenance person, engineer, line supervisor)

- All participants are empowered to take direct actions on the manufacturing process

- Preferred duration is five minutes (absolutely no longer than ten minutes)

- Takes place at or near the manufacturing process (usually as a stand-up meeting)

- Focuses on improving performance of the process constraint (the bottleneck)

- Sets realistic performance targets for the next SIC interval (attainable goals)

- Results in a set of written actions for the next SIC interval (with clear lines of accountability)

A Four-Part SIC Meeting Agenda

It is critical that SIC meetings be extremely efficient to quickly get the team back to the factory floor. The four-part meeting agenda outlined in this section is designed to do exactly that.

| Meeting Part | Description and Objectives |

|---|---|

| Review Previous Losses | Review data from the just-completed SIC interval:

|

| Assess Previous Actions | Review actions from the last SIC meeting:

|

| Identify Next Risks | Review the production plan for the next SIC interval:

|

| Decide Next Actions | Decide on the specific set of actions that the team should complete during the next SIC interval:

|

Simplified SIC Roadmap

An excellent way to gain a deeper understanding of SIC is to walk through an implementation example. This section provides a step-by-step roadmap for a simple and practical SIC implementation.

Step One – Identify Pilot Area

In this step, the target area for the pilot SIC program is selected. The ideal pilot area will have the following characteristics:

| Item | Description |

|---|---|

| Performance | Deficiencies in performance (the area has known opportunities for improvement) |

| Openness | Prospective team members who are open to new ideas, eager to improve, and work well together |

| Leader | A leader that will actively drive the process and focus the team |

| Infrastructure | Existing infrastructure for generating accurate real-time performance and loss data |

With the pilot area identified, work with the team to select a suitable SIC interval. When setting the SIC interval, consider the time needed to collect the relevant data. For most sites, a good starting interval is every four hours (beginning of shift and mid-shift correction), and a good long-term goal for intervals is every two hours (which provides more frequent course corrections).

Step Two – Identify Loss Metrics

Identify the core metrics that will be used to identify losses and drive the SIC process. For most companies, the de facto “gold standard” for manufacturing performance data is measuring OEE (Overall Equipment Effectiveness) with an additional breakdown of OEE loss categories into the Six Big Losses and a detailed breakdown of OEE Availability losses into Downtime Reasons.

If equipment is not the most significant driver for improved manufacturing performance, identify an alternate loss metric to drive effective decision-making within the SIC process. For example:

| Item | Description |

|---|---|

| Labor | A process that is highly labor-orientated may use a labor per unit produced metric |

| Yield | A process that suffers from heavy yield losses may use a yield-by-zone or yield-by-area metric |

Step Three – Verify Data Accuracy and Quality

SIC teams use performance data to drive their actions so it is essential that this data is accurate. To verify that the data collection system is effective, independently verify performance data for a minimum of four SIC intervals, preferably across a range of shifts and products. Key data points to verify include:

| Item | Description |

|---|---|

| Total | Total Quantity Produced |

| Reject | Reject Quantity Produced |

| Downtime | Downtime Minutes and Reasons |

| OEE | Overall Equipment Effectiveness (calculated from the above plus the Ideal Cycle Time) |

If the data being collected is not sufficiently accurate, look for root causes and take steps to correct the problem before going further. In some cases, it may be worthwhile to automate the data collection process to ensure better quality data for the SIC process.

Step Four – Create Tracking Tool

Create a simple way of capturing data and actions during SIC review meetings. This can be a printed form, a spreadsheet, a whiteboard, a flip chart – anything that works for the team.

Before using the first version of the tracking tool with the team, ensure that each member of the team tests the document through several SIC intervals to ensure that it is easy to follow and easy to complete. It is normal to make changes to the tracking tool before settling on a layout that works best for the team.

Step Five – Train Team and Start SIC Review Meetings

In order for an SIC process to be effective the team needs to understand the intent as well as the mechanics of the SIC process. A recommended approach to implementing SIC from the perspective of the SIC champion (typically a middle or upper management person who has been trained and mentored on the SIC process) is as follows:

| Item | Description |

|---|---|

| Goals | Brief the team on the goals of the SIC process and how it can help the team get better results, and the role this has in the company becoming a stronger and better competitor. |

| Demonstrate | Personally demonstrate the SIC process to the team and lead the process for the first week. This creates a benchmark for what the process should look like for the entire team. |

| Observe | After the first week, have the line supervisor lead the process while you observe. Allow the line supervisor to run reviews completely free of any interruptions from you. After each review, provide constructive coaching tips in one-on-one sessions. Repeat this process until you are confident that the line supervisor is ready to operate without ongoing supervision. |

| Reviews | Schedule a series of weekly and then monthly drop-in reviews to provide further coaching and to seek feedback on how well the SIC process is operating. |

Step Six – Sustain Progress through Audits

The secret to creating a sustainable process is regularly auditing the process to identify and reinforce great behavior. In order to create a sustainable process both middle management and upper management have an important role to play:

| Item | Description |

|---|---|

| Middle Management | Middle management should audit at least three or four review meetings every week – an investment of less than an hour per week to help guarantee the success of a program that will continually drive improvements in production performance. |

| Upper Management | Upper management should audit the SIC program one month after starting and then on an ongoing monthly or quarterly basis. The goal is to help ensure that the program remains effective. Review and fine-tune the SIC process, including what data is collected, how it’s recorded, and how actions are reviewed. Provide ongoing feedback and coaching to middle management. |

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.