Hoshin Kanri

What Is Hoshin Kanri?

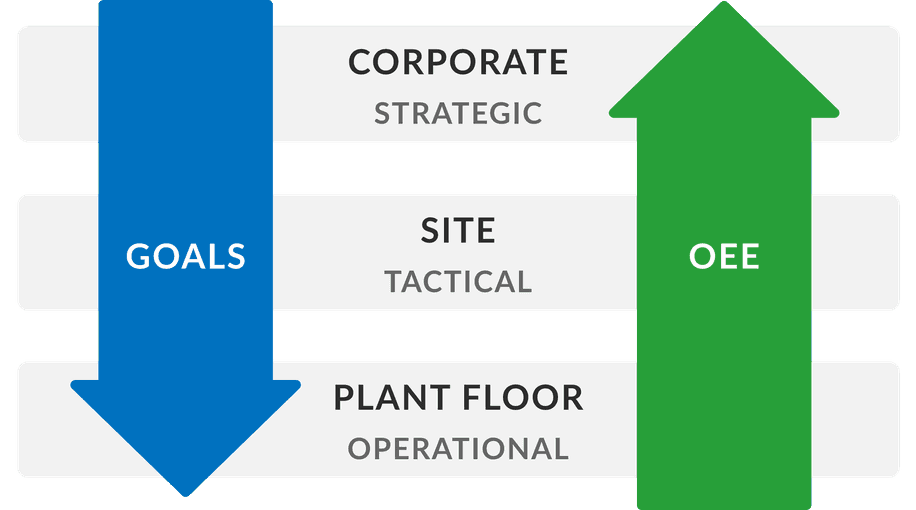

Hoshin Kanri (also called Policy Deployment) is a method for ensuring that a company's strategic goals drive progress and action at every level within that company. This method eliminates the waste that comes from inconsistent direction and poor communication.

Hoshin Kanri strives to get every employee pulling in the same direction at the same time. It achieves this by aligning the goals of the company (Strategy) with the plans of middle management (Tactics) and the work performed by all employees (Operations).

How to Implement Hoshin Kanri

One way to understand Hoshin Kanri is to walk through a typical set of implementation steps.

Step One – Create a Strategic Plan

Hoshin Kanri starts with a strategic plan (e.g., an annual plan) that is developed by top management to further the long-range goals of the company. This plan should be carefully crafted to address a small number of critical issues. Key items to consider when developing the strategic plan are:

Focus on Five Goals

Focus on five goals (or less). The mere act of writing down goals can create a (false) feeling of progress – and more goals feel like more progress. In reality, a goal only expresses intent; taking action is the hard part. Every company has finite resources and energy…and a limited attention span. Focusing on a small number of goals makes success far more likely than dissipating energy across dozens of goals. Or looking at it another way…if everything is important; nothing is important.

Put Effectiveness First

There is a well-known distinction between efficiency and effectiveness: efficiency is doing things right while effectiveness is doing the right things. Strategic goals need to be effective – doing the right things to take the company to the next level. If a goal doesn’t have that kind of broad impact, it’s probably not strategic.

Understand Evolution vs. Revolution

Goals can be evolutionary (incremental goals usually achieved through continuous improvement) or revolutionary (breakthrough changes with dramatic scope). Both are legitimate and important forms of improvement.

Get Top Down Consensus

Top management is responsible for developing the strategic plan – it’s one of their most important responsibilities. But taking the time to consult with middle management serves two useful purposes:

- It provides additional perspective and feedback that helps craft stronger, more informed strategies

- It creates a sense of shared responsibility for the plan and significantly more buy-in from middle management

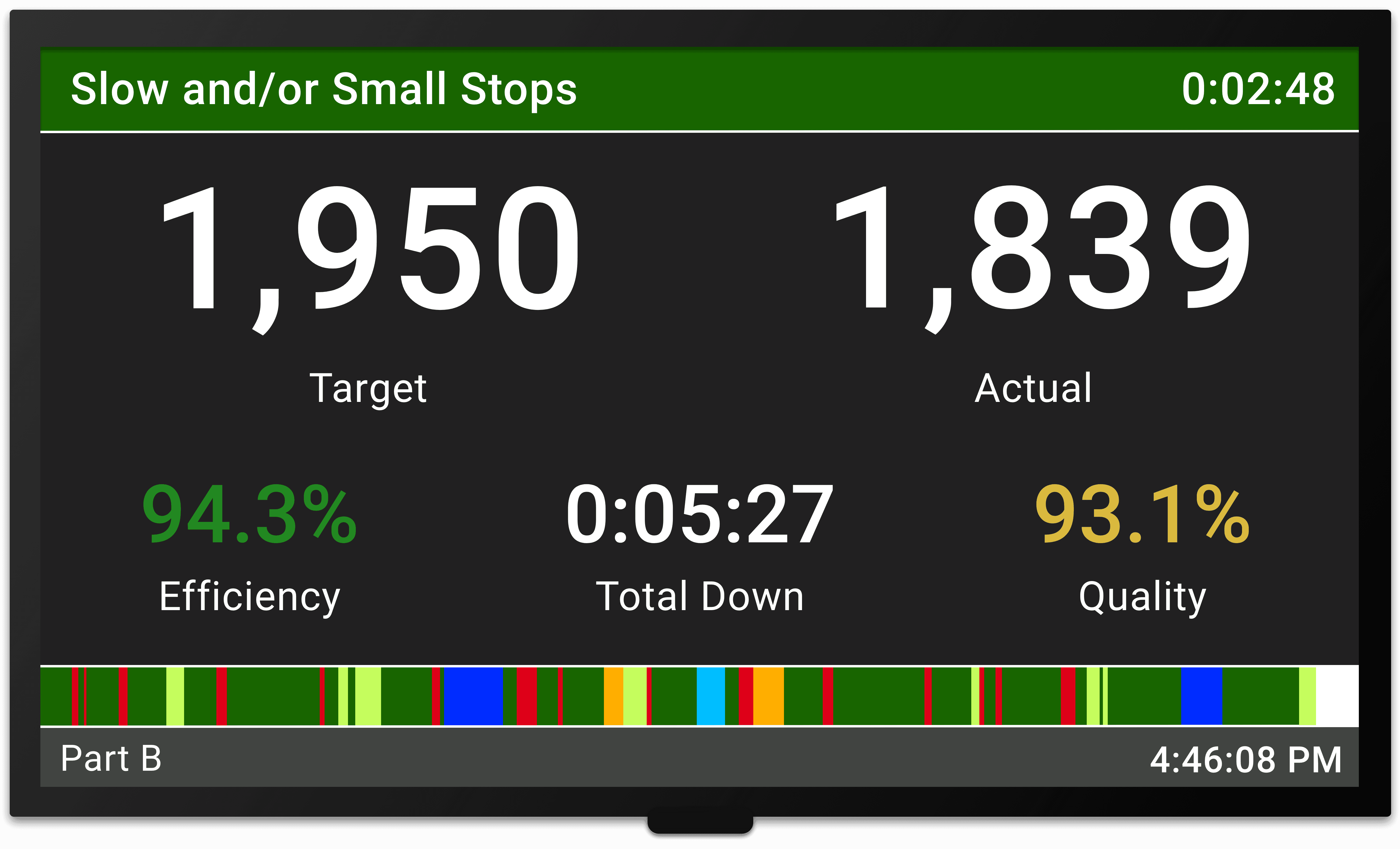

Set Careful KPIs

Key Performance Indicators (KPIs) provide the means for tracking progress towards goals. They also have a considerable ability to drive behavior. So choose KPIs with care. It is essential to think through whether the selected KPIs will drive the desired behavior without unintended side effects. For example, more than one company has found that a single-minded pursuit of efficiency can lead to unintended consequences, such as excess inventory (larger batches means fewer changeovers) and reduced quality (a subtle “fix it later” pressure creeps in to keep lines running).

Own the Goal

Every goal should have an owner – a facilitator and coach who has the skills and authority to see the goal through to conclusion successfully.

- As a facilitator, the goal owner will remove roadblocks and smooth the path to progress.

- As a coach, the goal owner will track progress and intercede if things get off track.

Step Two – Develop Tactics

At a departmental level, mid-level managers develop tactics that will best achieve the goals as laid out by top management. One of the most important aspects of this process is “catchball": a back and forth exchange with top management to ensure that the strategy and goals are well understood, that there is strong alignment between strategy and tactics, and that the KPIs are meaningful and appropriate.

Tactics may change throughout the course of fulfilling the strategy; flexibility and adaptability are important characteristics of the process. As a result, it is helpful to have regular progress reviews (e.g., monthly), at which time results are evaluated and tactics are recalibrated.

Step Three – Take Action

At the plant floor level, supervisors and team leaders work out the operational details to implement the tactics as laid out by mid-level managers. Once again, the principle of catchball applies, to ensure that activities at the plant floor (and other areas of the company) are strongly aligned with tactics and strategy.

This is the level where goals and plans are transformed into results. This is Gemba (the place where real action occurs). Therefore, managers should stay closely connected to activity at this level (e.g., regularly practicing “management by wandering around”).

Step Four – Review and Adjust

So far the steps have focused on cascading strategic goals down through levels of the company; from top management all the way down to the plant floor. Equally important is the flow of information in the other direction – information about progress and results. It is this second flow that creates a closed-loop system – enabling control and adjustment of the entire process.

Progress should be tracked continuously and reviewed formally on a regular basis (e.g., monthly). These progress checkpoints provide an opportunity for an adjustment of tactics and their associated operational details.

Additional Considerations

Hoshin Kanri is for Everyone

Hoshin Kanri is not as well-known or “popular” as some of the other lean tools – but it is an extremely valuable tool. Although this policy deployment method fits most naturally within a well-developed lean culture, where continuous improvement is firmly ingrained at all levels of a company, virtually any organization can benefit from its core principles:

- Visionary Strategic Planning: focusing on the things that really matter

- Catchball: building workable plans through consensus

- Measuring Progress: carefully selecting KPIs that will drive the desired behavior

- Closing the loop: using regular follow-up to keep progress on track

Benefits of a Flat Management Structure

It should be pretty obvious that a flattened management structure is beneficial to Hoshin Kanri. The fewer levels there are, the easier it is to cascade goals down and the fewer opportunities there are for strategy to be diminished through successive layers of translation. Fewer layers also means faster decision-making.

Some very large organizations have flat management structures. One of the best known is Nucor Steel, which has approximately 12,000 employees and only four layers of management between the CEO and line-level employees. In fact, a common joke is you can go from Janitor to CEO at Nucor with only five promotions. In contrast, a typical Fortune 500 company has 8 to 10 layers of management.

Create a Shared Vision

People perform best when they have a purpose. When they understand not just what to do – but why it’s important. One of the benefits of Hoshin Kanri is that it can help to create that purpose; providing focus and drive towards specific and important goals.

So, it’s worth putting some effort into creating a shared vision of the strategic plan (the future state; the destination) and associated tactics (the path to get there). Ensure as many employees as possible are given an opportunity to understand why the strategic goals are important and how the tactics and operational details support those goals.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.