Essence of Lean

What Is Lean Manufacturing?

The core idea of lean manufacturing is quite simple: relentlessly work on eliminating waste from the manufacturing process.

What is waste? It can take many forms, but the underlying idea is to eliminate anything and everything that does not add value from the perspective of your customer.

Another way to look at lean manufacturing is as a collection of tools, techniques, and principles that have been proven to be effective at driving waste out of the manufacturing process.

For this topic, we will explore the essence of lean from two perspectives:

- Five Lean Principles: The classic process for implementing lean.

- Seven Deadly Wastes: The traditional categories of waste in manufacturing processes.

Five Lean Principles

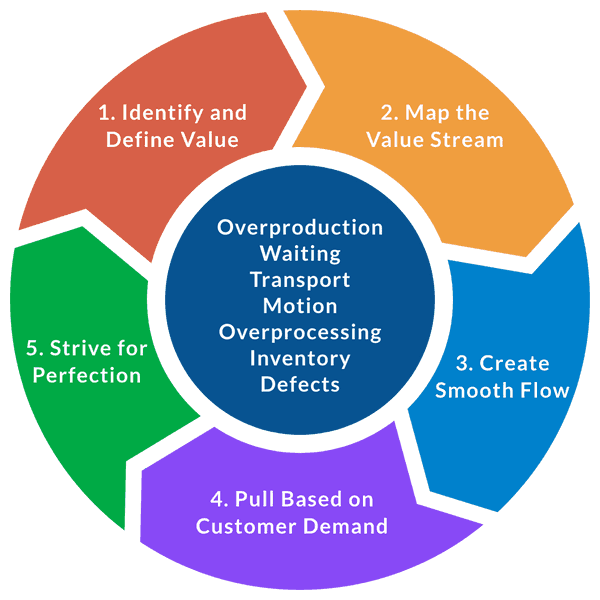

What Are the Five Lean Principles?

The Five Lean Principles are a proven methodology for integrating lean into your manufacturing process. These principles are effective because they help you:

- Look at your process from the perspective of your customer and identify what they deem valuable.

- Distinguish steps and activities in the process that provide value from those that create waste.

- Streamline the process to be free of bottlenecks and delays.

- Align to customer demand and adjust quickly to changes in that demand.

- Promote an internal culture of continuous improvement and excellence.

The end result will be better value for your customers, reduced waste, increased productivity, an advantage over your competition, and, ultimately, larger profits.

Let’s review each of the five principles.

Identify and Define Value

Value is defined in the context of the products and/or services that you provide for your customers:

- What do your customers truly want?

- What are they willing to pay for?

- What do they perceive as valuable?

As you can see from these questions, value is defined purely from the customer perspective. In other words, the goal is to identify your customer’s needs - both explicit (stated) and implicit (unsaid). That’s why we recommend that you go beyond direct customer feedback (reactive) and conduct your own research (proactive).

If you do not manufacture directly for end customers, you can consider your customers to be the different segments of your ultimate market.

Map the Value Stream

Once you have a good understanding of what your customers value, identify the steps (and the activities within the steps) in your process that create and reinforce this value (productive) versus the steps and activities that do not create and reinforce this value (wasteful). This is known as value stream mapping.

More specifically, value stream mapping articulates the current and future states of processes in a way that highlights opportunities for improvement. From an agile perspective, it provides you with a roadmap for improvement that will help you to iteratively reach a desired future state.

To map a value stream, identify every step in the entire manufacturing process, from upstream supply to downstream delivery. The more care you take in accurately identifying and characterizing each step, the more opportunities you will have to improve.

Once the process is mapped into steps, ask the following three questions for each step:

- Does this step, and its activities, bring value to the customer?

- Does this step, and its activities, move your product or service downstream towards the customer?

- Does this step, and its activities, flow smoothly, without impediments, within the context of the value stream?

These questions will help you differentiate between value and waste. Specifically, categorize each step, and its activities, from the perspective of value (and waste).

| Does a Given Activity... | Description |

|---|---|

| Add Value? | The customer is willing to pay for this work. No immediate action is required. |

| Create Necessary Waste? | The customer would prefer not to pay for this work. This activity does not directly add value but is necessary to ensure that your final product or service is valuable. Strive to minimize this activity. |

| Create Unnecessary Waste? | The customer is not willing to pay for this work. This activity does not add value. Strive to completely remove this activity. |

Create Smooth Flow

Now that you have a much better understanding of the steps and activities of your manufacturing process, you are in a better position to create a smoothly flowing process - ideally one which is free of bottlenecks, inventory, and delays.

Examples of strategies to improve flow include:

- Reduce Changeover Times: making it faster to switch between products so you can be more responsive to your customers.

- Avoid Batch Operations: batching is the opposite of flow and inherently creates bottlenecks, queues and inventory.

- Organize Equipment: to match the natural flow of the value stream so flow is inherent in your process.

Enabling your products and/or services to flow smoothly will dramatically improve your customer alignment and your ability to respond to changes in their demand.

Pull Based on Customer Demand

With better flow it is easier to schedule the manufacturing process such that product is pulled through the process based on customer demand. Typically this involves manufacturing in smaller production runs that are directly tied to customer orders.

Pulling production through the value stream makes it much easier to reduce finished product inventory. This is important because large finished product inventories and large amounts of WIP (work-in-process) are reservoirs of waste.

It is also important to differentiate between inventory that you:

- Need to protect your manufacturing process from external supply shocks (necessary waste)

- Don’t need to protect your manufacturing process as it is internally created (unnecessary waste)

As recent history has shown, the real world is very messy, and there can be significant unanticipated supply chain shocks. One takeaway is the importance of building and maintaining productive and positive long-term relationships with suppliers, so they are willing to listen to your concerns and help where they can.

Strive for Perfection

Improvement is a journey - not a destination. The five lean principles are an iterative process that will bring further value as they are repeated. Continue to apply these principles to your manufacturing process based on what you learn about your customers, best practices for manufacturing, and the characteristics of your process.

Your overarching goal should be to create a culture of continuous improvement. When it truly becomes your company’s culture, it also becomes self-sustaining. Consider achieving this as a key responsibility and natural outcome of effective leadership.

Seven Deadly Wastes

Let’s talk a bit more about waste. Traditional lean identifies seven key areas of waste – typically referred to as the Seven Deadly Wastes. These are described below along with suggested countermeasures. Don’t worry if the countermeasures are not immediately “actionable” for you – right now they can be considered simply as a roadmap for the future.

Overproduction

What is Overproduction?

Making something before it is truly needed. This is a particularly serious form of waste because it leads to excess inventory that is often used to mask other underlying problems and inefficiencies.

What are Countermeasures for Overproduction?

- Pace production so the rate of manufacturing matches the rate of customer demand (Takt Time).

- Use a pull system to control how much is manufactured (Kanban).

- Reduce setup times so that smaller batches can be economically manufactured (SMED).

Waiting

What is Waiting?

Time when work-in-process is waiting for the next step in production (no value is being added). It can be truly illuminating to look at the time from order to shipment and ask – how much of that time is actually spent on true value-added manufacturing.

What are Countermeasures for Waiting?

- Design processes so that the flow is continuous and there are minimal (or no) buffers between steps in production (Continuous Flow).

- Use standardized work instructions to ensure that a consistent method and consistent times are used for each step of production (Standardized Work).

Transport

What is Transport?

Unnecessary movement of raw materials, work-in-process or finished goods.

What are Countermeasures for Transport?

- Design a linear, sequential flow from raw materials to finished goods (Value Stream Mapping).

- Make sure work-in-process is not placed into inventory (Continuous Flow).

- Avoid continual changing of job priorities (Theory of Constraints).

Motion

What is Motion?

Unnecessary movement of people (movement that does not add value).

What are Countermeasures for Motion?

- Ensure that work areas are logically organized (5S).

- Consider alternate arrangements of equipment that reduce motion (Value Stream Mapping).

Overprocessing

What is Overprocessing?

More processing than is needed to produce what the customer requires. This is often one of the more difficult wastes to detect and eliminate.

What are Countermeasures for Overprocessing?

- Compare customer requirements to manufacturing specifications (Kaizen).

- Look for potential simplifications to the manufacturing process (Kaizen).

Inventory

What is Inventory?

Product (raw materials, work-in-process, or finished goods) quantities that go beyond supporting the immediate need.

What are Countermeasures for Inventory?

- Bring raw materials in only as they are needed (Just-In-Time).

- Reduce or eliminate buffers between steps in production (Continuous Flow).

- Refer to Overproduction countermeasures (Takt Time, Kanban, and SMED).

Defects

What are Defects?

Production that is scrap or requires rework.

What are Countermeasures for Defects?

- Design processes so they are less likely to produce defects (Poka-Yoke).

- Design processes to detect abnormalities so they can be immediately corrected (Jidoka).

- Look for the single most frequent defect and determine why it occurs (Root Cause Analysis).

- Create work instructions that provide a consistent method of manufacturing the part. (Standardized Work).

Lean concepts become a lot more intuitive and easy-to-understand when they are traced to the ultimate goal – eliminating waste.

AN EIGHTH DEADLY WASTE

An extremely important form of waste that is not represented within the Seven Deadly Wastes is unused human potential. This form of waste results in all sorts of lost opportunities (e.g., lost motivation, lost creativity, and lost ideas).

One of the reasons that this from of waste is often underemphasized or even ignored at companies is that responsibility for it lies squarely on the shoulders of management. Unused human potential often results from management policies and management styles that diminish employee contributions. By way of contrast, developing strong coaching skills for managers can be very effective in strengthening employee contributions.

WHAT YOU SHOULD DO NEXT...

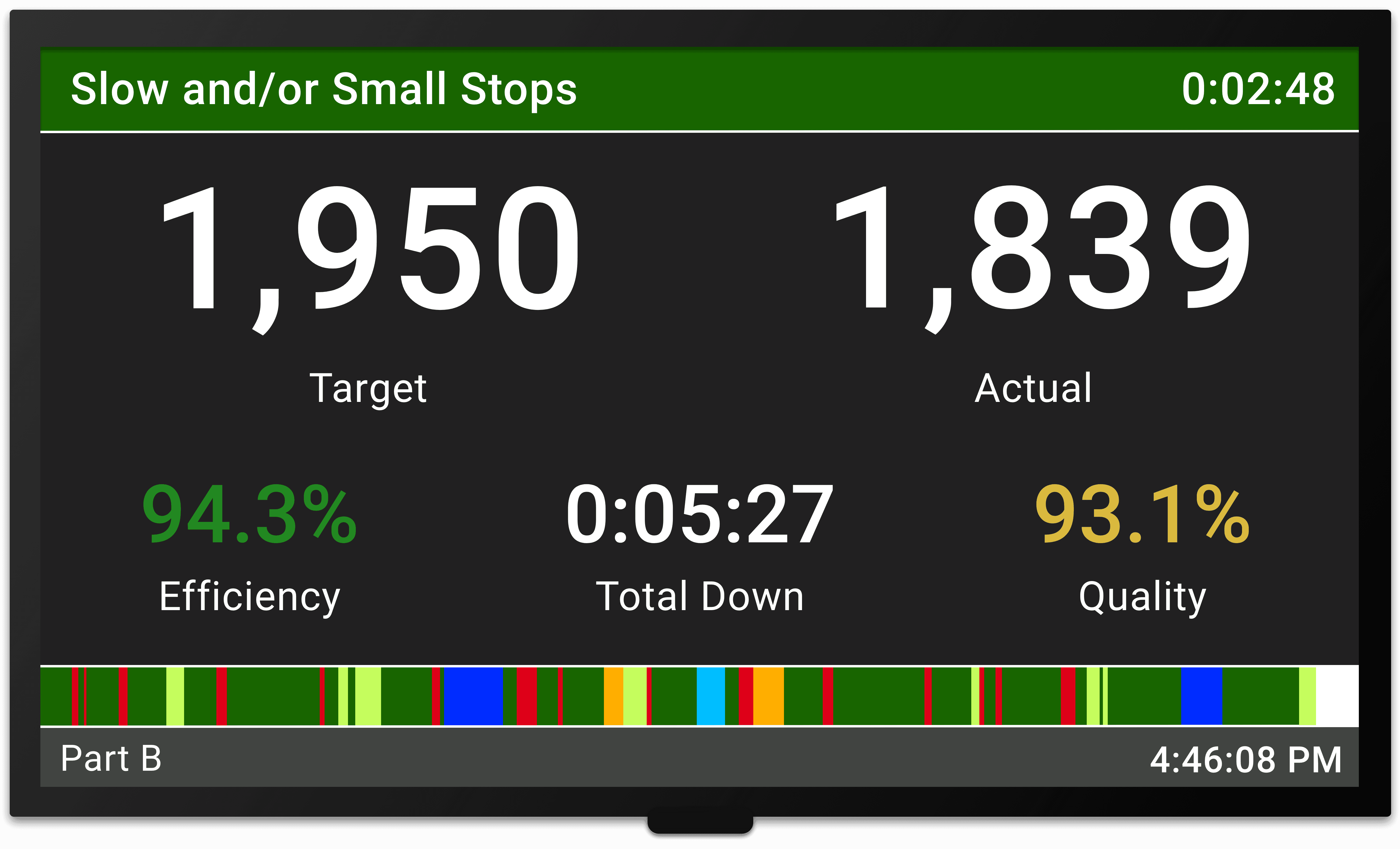

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.