Agile Manufacturing

What Is Agile Manufacturing?

Agile manufacturing is a manufacturing methodology that places an extremely strong focus on rapid response to the customer – turning speed and agility into a key competitive advantage. It represents a very interesting approach to developing a competitive advantage in today’s fast-moving marketplace. An agile company is in a much better position to take advantage of short windows of opportunity and fast changes in customer demand.

Why Is Agile Manufacturing Effective?

Agile manufacturing is effective because it acknowledges the realities of the modern marketplace and transforms them into a competitive advantage. It directly addresses the following issues:

- Consumers love instant gratification. They are increasingly getting used to it and they are often willing to pay for it. For example, have you ever ordered a product with overnight shipping…waiting in eager anticipation?

- Consumers love choice. They prefer to get a product exactly as they want it…without compromise.

- Consumers are fickle. Their interests shift and move in unpredictable ways.

Agile is of particular value for manufacturers in countries with large, well-developed local markets and high labor costs (e.g., the United States). It leverages proximity to the market by delivering products with an unprecedented level of speed and personalization, which simply cannot be matched by offshore competitors. It turns local manufacturing into a competitive advantage.

4 Key Agile Manufacturing Elements

There are four key elements for agile manufacturing:

- Modular Product Design: designing products in a modular fashion that enables them to serve as platforms for fast and easy variation

- Information Technology: automating the rapid dissemination of information throughout the company to enable lightning fast response to orders

- Corporate Partners: creating virtual short-term alliances with other companies that enable improved time-to-market for selected product segments

- Knowledge Culture: investing in employee training to achieve a culture that supports rapid change and ongoing adaptation

Lean vs Agile Manufacturing

Lean manufacturing is generally considered to be a precursor to agile. Many lean practices are also enablers for agile manufacturing. For example, manufacturing in small batches (or even better – manufacturing with one-piece flow), fast changeovers, and a culture of continuous improvement are all foundations that pave the road to agile manufacturing.

It is quite interesting to see how lean manufacturing tools and techniques can benefit areas that extend beyond the core lean objective (improving productivity and profitability by relentlessly eliminating waste). Agile manufacturing is one such area.

Is Agile Manufacturing for Me?

For any given business segment, ask the following questions:

- Is there a potential market for a personalized fast-delivery version of one of our current products?

- Is there a new product that we can develop that is within our company’s sphere of competence (or alternately that can be co-developed with a partner) that would strongly benefit from personalization and fast delivery?

Agile Manufacturing Example

The 3-Day Car Project (in the UK) and the 5-Day Car Project (in the EU) focused on the idea of transforming automotive manufacturing into a build-to-order system (i.e., each car built for a specific customer order) with delivery times measured in days instead of weeks or months. Considering that the actual manufacturing time for a car is on the order of 1.5 days, this is a realistic goal – although perhaps not yet an attainable goal. But without a doubt – the company that gets there first will have created a significant competitive advantage.

WHAT YOU SHOULD DO NEXT...

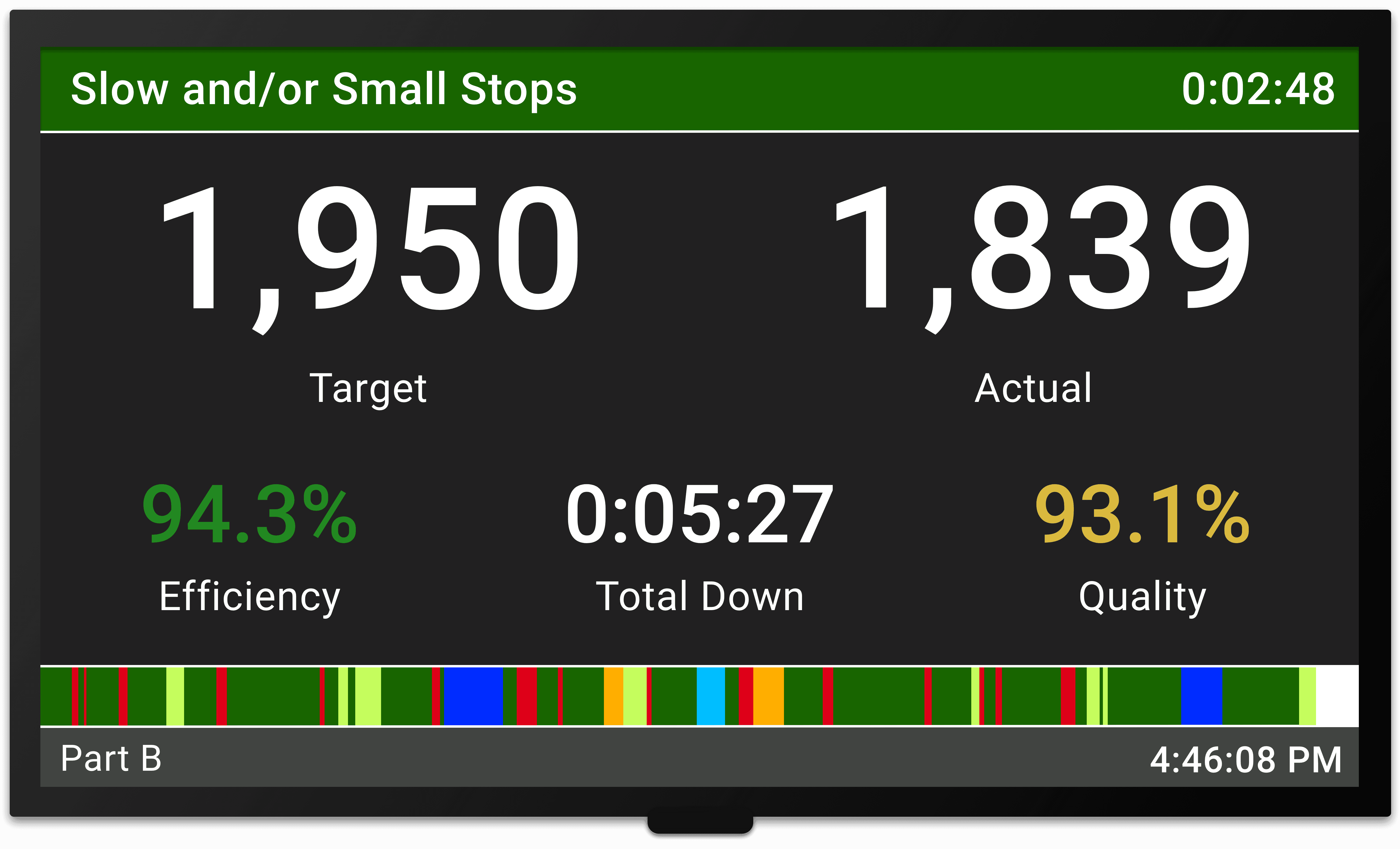

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.