The Ultimate Guide to 5S: Meaning, Methodology, and Implementation

What Is 5S?

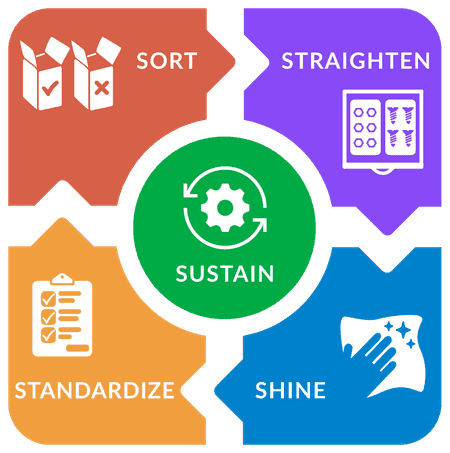

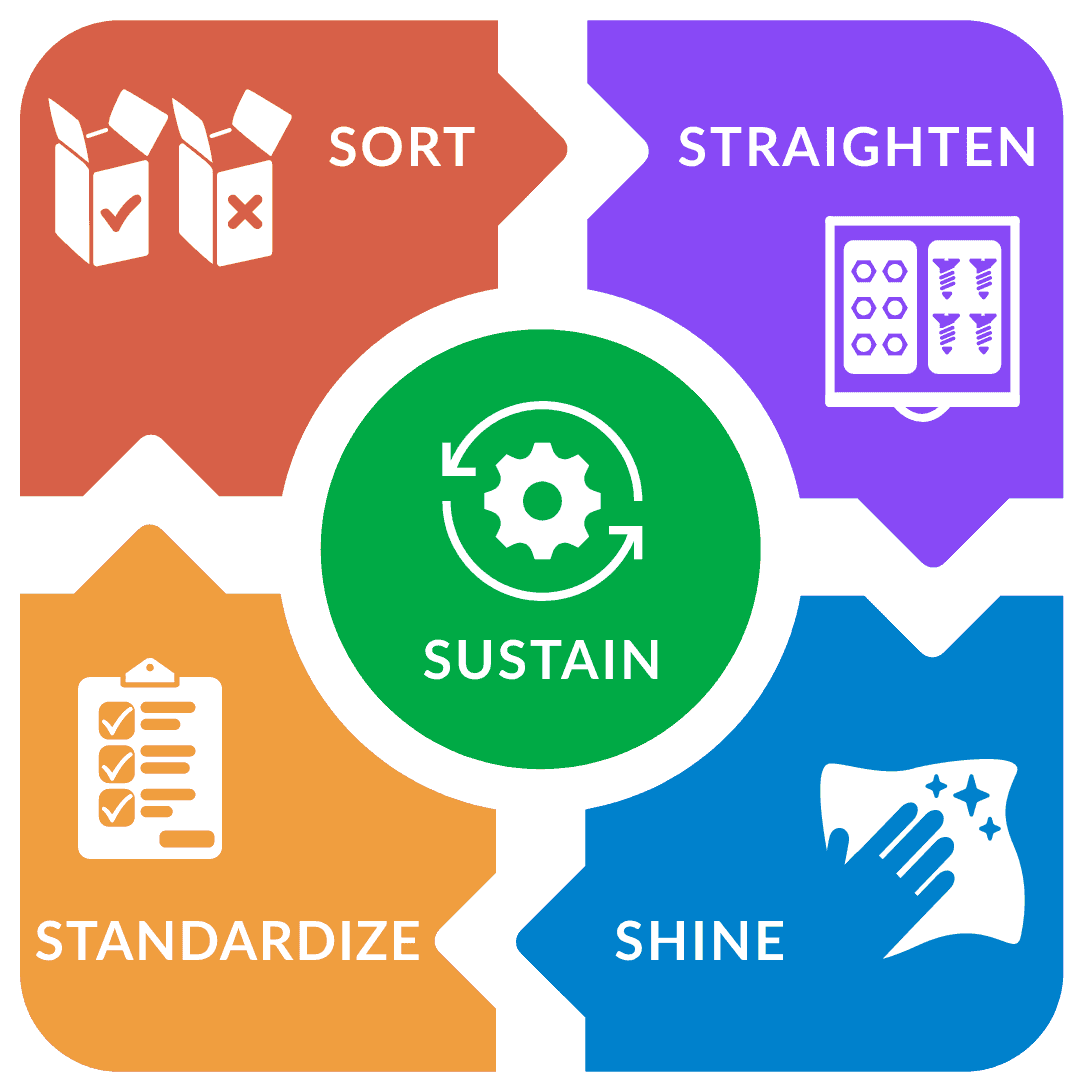

5S is a five-step methodology that creates a more organized and productive workspace. In English, the 5S’s are: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.

What Is the 5S Methodology?

Have you ever tried to locate a small object in a messy closet or prepare a favorite meal on a cluttered countertop? Chances are, you were unable to quickly find what you were looking for — which interfered with your ability to complete the task efficiently. Even familiar tasks are far more challenging when you can’t easily obtain what you need due to a disorganized or overcrowded space.

The 5S methodology was created to help the manufacturing industry address exactly these kinds of issues, so organizations can remain more agile and competitive. In fact, the 5S philosophy might best be summarized by the time-honored adage:

If you’re familiar with Japanese author and TV personality Marie Kondo, then you may have heard of the “KonMari” system. Kondo developed this method to help simplify, clear, and streamline cluttered living spaces. Those who practice KonMari have reported a sense of enhanced focused, improved decision-making, and more effective prioritization.

Imagine these dynamics applied to your own manufacturing work areas, and you begin to understand why it’s well worth exploring 5S in greater detail. 5S may primarily involve simplification — but its origins, influence, and advantages are richly multifaceted.

5S Meaning: Origins and Elements

It is perhaps unsurprising that this widely heralded method for efficiently organizing manufacturing workspaces was originally developed in Japan. Tourists — and those who have seen photographs and videos of Japanese villages and landscapes — often notice a distinctive orderliness, serenity, simplicity, and symmetry that pervades the entire culture. Japanese gardens and bonsai trees are methodically pruned and tended. Streets are often strikingly free of debris. Many of the shops and gathering areas are meticulously neat and tidy. Orderly spaces and processes seem to be inherently valued, even revered.

So, it’s no surprise that 5S had its early origins in the Japanese automotive industry. It was initially part of the Toyota Production System (TPS), created in the 1950s by the Toyota Motor Company to help the organization become more agile in an increasingly competitive marketplace. Toyota sought to radically eliminate any part of the automotive production process that contributed to muda, the Japanese word for “waste.”

A key component of this overall strategy involved rearranging and organizing the shop floor in a way that would keep it consistently neat and orderly. This minimized the amount of time spent hunting for tools and equipment. It also reduced unnecessary movement that removed focus from the core tasks at hand, and it reduced the misplacement of raw materials.

As described in our article on the history of 5S, this burgeoning 5S framework contributed to the conception of lean production. For now, let’s explore the 5S methodology as it has evolved to exist today.

5S Methodology: Sequential Simplicity

As the TPS framework became more established over time, the system began to coalesce around five core focus areas. Each of these areas could be described using a word that began with the letter “S,” which is what inspired the 5S name. Here are the original Japanese terms for these core elements, each of which specifically describes a sequential step of 5S:

5S Japanese Words

- 1Seiri: to sort through and eliminate that which is not truly needed

- 2Seiton: to organize what remains after sorting

- 3Seisou: to clean and inspect the work area

- 4Seiketsu: to create standards that support a repeatable process

- 5Shitsuke: to consistently apply these standards across work areas

As we discuss here, TPS led to significantly increased productivity. It was only a matter of time before Western manufacturing organizations began taking notice, and the 5S system solidified into a paradigm that became substantially more widespread. Eventually, the original Japanese terms were translated into English counterparts that also began with the letter “S.” These English language equivalents are as follows:

5S Meaning in English

- 1Sort: equivalent of seiri

- 2Straighten: equivalent of seiton

- 3Shine: equivalent of seisou

- 4Standardize: equivalent of seiketsu

- 5Sustain: equivalent of shitsuke

At their core, these 5S activities build the discipline needed for substantial and continuous improvement by creating (and sustaining) efficient and effective work areas.

5S is critical to maintaining order in the ever-evolving, complex factories of today’s world. While it’s a significant amount of work to implement, it is straightforward, especially if you encourage employee buy-in and follow the five simple steps below.

How to Implement 5S in Your Factory

Even if you’re still learning about 5S, you can move forward and begin reaping the benefits. How can you introduce your team to each step in a way that encourages active participation? Read on to find out!

1. Sort (seiri)

What Is Sort?

The Sort step separates items in your workspace that you know you need from items that you do not or may not need. Move the latter to a “red tag” holding area.

Why Do You Need Sort?

Sort creates a more productive workspace by removing unneeded clutter (and eliminating distractions). It also is a first step towards opening up space for other uses.

How to Implement Sort

Sorting involves separating and categorizing items based on their usefulness. Set aside a specific timeframe, and encourage your employees to look at every item in their workspace. Ask them to decide whether each item is truly necessary for daily operations.

We recommend sorting items into four categories:

- 1Items needed in this work area. These are items you know that you regularly use in the context of this work area and thus will remain there.

- 2Items needed in another work area. These are typically misplaced items. If an item is used in another work area, “sort” it into that area by delivering it to the responsible team member.

- 3Items you may need. For items you are unsure about, use the 5S “red tag” system. Mark such items with red tags, which at a minimum, should have written on them: the name of who tagged the item, why it is thought to no longer be needed, a proposed review date, and the name of the manager who must approve of disposal. Move the item to a red tag holding area, which should be organized by review month to make it easy to manage.

- 4Items you do not need. These are items that you are 100% confident are not needed. They should be immediately: discarded, recycled, donated, or sold if in good condition.

Key “Sort” Advantages Include

- More organized workspaces

- Reduced clutter

- Lower risk of accidents thanks to clearer pathways and more open spaces

- Streamlined workflow that helps reduce unnecessary movement

- Increased focus, which can reduce stress and enhance employee morale

Industry Example: Switch and Router Manufacturing

Accuracy is imperative in an electronics manufacturing environment. This is because product safety is a top priority, so it’s important to create high-quality goods that perform consistently and reliably. Sorting specialized tools and increasingly miniaturized electronic components can greatly reduce the risk of damaged or misplaced materials that could lead to inferior output.

2. Straighten (seiton)

What Is Straighten?

The Straighten step thoroughly organizes the items that remain after sorting, making frequently used items easily accessible and providing every item a clear and easy-to-find home.

Why Do You Need to Straighten?

Straighten enables every item to have a specific home where it can be easily found and to which it can be easily returned. It reduces the waste from excess motion, as items are placed in more ergonomic locations. It is also the second step on the path to opening up space that can be used strategically toward the goal of improving production.

How to Implement Straighten

After you’ve sorted items, it’s time to decide how you want to organize them. Straightening involves systematically organizing the newly de-cluttered workspace.

We recommend the following methodology:

- 1Make time. Set aside a specific interval of time, and ask employees to examine the remaining items in their work area.

- 2Provide easy access to frequently used items. For each item, have team members designate a location that optimizes order and accessibility. The key to reducing waste from excess motion is to place frequently used items within easy reach. Encourage your team to consider how they move about their space so they can minimize unnecessary motion.

- 3Group like items. Group the remaining items into logical categories and brainstorm the best way to organize and store each of these categories.

- 4Equip teams with organizational aids. Provide: permanent markers, peg boards, hooks, chalk, and/or masking tape. Peg boards create designated hanging spaces that keep tools off the floor and in one predictable spot. Tape and chalk can help specify pathways along the floor that need to be kept clear. Shelves and bins can create compartmentalized storage space.

- 5Utilize visual designs. For each group, decide on the best way to make it clear when an item is missing or misplaced. A classic example is creating a shadow board for tools.

- 6Unleash the labeler. If an item is too big to put into a container, consider giving it a frame and putting a label on the item in addition to the frame. Labels can help highlight the contents of shelving areas, crates, and cubicles.

- 7Be intentional. Encourage employees to carefully evaluate details such as distance, height, and reachability — factors that can minimize strain and enhance ergonomic comfort.

- 8Be agile. Your initial straighten pass will likely deliver a significant improvement - but you are also likely to overlook some potential improvements. Plan a 5S team meeting with a focus on straightening at the one and two week points, and brainstorm further improvements as part of your initial implementation.

Key “Straighten” Advantages Include

- Less worker fatigue and strain, which supports healthy ergonomics

- Less extraneous motion to help streamline response time

- More organized work areas

- Clearer pathways that lower the risk of accidents

- Improved team engagement and communication

Industry Example: Apparel Manufacturing

Clothing typically includes functional details like zippers and buttons, as well as decorative embellishments like beads and trim. Straightening the textile manufacturing production space makes it easier for workers in this industry to quickly locate key elements on a tight production schedule. It also provides added space for assemblers and tailors to work, minimizing the risk of muscular fatigue and repetitive motion injuries.

3. Shine (seisou)

What Is Shine?

The Shine step elevates the work area by ensuring thoroughly cleaned and inspected tools, equipment, and other items. It also can include routine maintenance on equipment, which is one of the ways it flows directly into TPM.

Why Do You Need to Shine?

Shine creates a work environment that engages and empowers operators by giving them more responsibility and agency over their work area. It also helps them to identify problems before they interfere with production.

For example, in a clean work environment, it is much easier to spot emerging issues such as fluid leaks, material spills, metal shavings from unexpected wear, hairline cracks in mechanisms, etc.

How to Implement Shine

After you’ve straightened items, it’s time to elevate the work area by cleaning, inspecting, and in some cases, performing routine maintenance.

We recommend the following:

- 1Create a schedule. Encourage employees to create a “shine checklist” that summarizes which items need to be cleaned or wiped down, how often, and by which individual(s).

- 2Grab the metaphorical spray bottle. Provide ready access to the appropriate: cleaning solutions, buckets, gloves, rags, dustcloths, and/or mops. Using appropriate cleaners and tools, make the work area sparkle. With every sweep, mop, brush, wipe, wash, and wax, strive to return your workspace to its former glory. Be Miyagi.

- 3Find the source. The guiding principle of this 5S step is “clean to understand.” If there are any signs of leaks, spills, or unexpected debris, strive to understand the source. It is likely an early warning of a future problem.

- 4Inspect. After cleaning each item, take a moment to look it over and examine its condition. Does it need updating, maintenance, or repair? Carry out cleanliness inspections at regular intervals — even occasionally unannounced — to ensure that workers are adhering to established protocols and schedules.

- 5Take initiative. Encourage your employees to share feedback and identify ongoing areas for improvement.

Key “Shine” Advantages Include

- Less buildup of grease and grime

- Reduced risk of equipment malfunctions and tool breakage

- Enhanced efficiency

- Greater sense of employee ownership, communication, and pride

- Cleaner, more hygienic manufacturing environment

Industry Example: Soft Drink Manufacturing

In the beverage industry, it’s vital to reduce the risk of bottle breakage and cross-contamination to maintain consumer health and well-being. Bottling also involves numerous steps including filling, capping, labeling, grouping, and packaging. Regularly cleaning and inspecting the work area promotes a hygienic production space, smoother equipment operation, and a more predictable flow of materials through the line. It may also help to minimize maintenance issues at the constraint.

4. Standardize (seiketsu)

What Is Standardize?

The Standardize step is a bridge between the first three 5S steps (Sort, Straighten, Shine) and the last step (Sustain). In this step, your goal is to capture best practices for 5S as standardized work for your team.

Why Do You Need to Standardize?

Standardize makes 5S repeatable. It transforms 5S from a one-off project to a reproducible set of activities.

How to Implement Standardize

It’s time to make sure all your hard work continues to pay dividends into the future. Standardizing involves reviewing the measures already taken above, and documenting a repeatable process that supports a consistent and uniform approach over time.

To do so, we recommend that you:

- 1Document in pairs. Have one team member walk through each 5S task as another team member documents it to ensure nothing important is missed. Check that steps are written in a way that all team members can follow.

- 2Capture the essence. We are huge proponents of simplicity (and agile). Capture the essence of each task and no more. Otherwise, your documentation will be difficult to maintain.

- 3Prefer checklists. Checklists feel easy. Short checklists feel even easier. A great format is providing a name for each task that serves as a quick reminder and a more detailed description for training.

- 4Organize to simplify. Organize your checklists by: role, shift, and frequency (daily, weekly, monthly). This will make the 5S process much less intimidating to your team.

- 5Review and consolidate. Collaboratively review and consolidate these notes, gradually creating more formalized documentation that can serve as an orderly, systematic procedure. Your goal should be providing clear yet detailed steps that can help others repeat each activity smoothly and efficiently.

- 6Emphasize accountability. Assign teammates to review each section of your documentation and make updates at specified intervals.

- 7Use descriptive names. Name your guide in a way that incorporates a version number and date. This information can then be modified whenever a new document is published, so everyone knows they’re working from the latest guidelines.

Key “Standardize” Advantages Include

- Improved consistency and organization across workspaces

- Sense of employee pride, collaboration, ownership, and engagement

- Increased employee compliance

- Enhanced collective attention to detail

- Repeatability that supports steadily increasing productivity, employee morale, and product quality

Industry Example: Cosmetics Manufacturing

The cosmetics industry is another area where consumer health and well-being are paramount. Even organizations that fabricate compacts, casings, and exterior packaging aren’t immune to these requirements.

For instance, it’s important to achieve a consistent level of quality that guards against breakage, cracking, or shards becoming intermingled with the cosmetic itself. A standardized 5S process ensures that the workspace is organized, cleaned, and regularly inspected to established protocols over time. This supports team engagement, ongoing efficiency, and a sense of process ownership.

5. Sustain (shitsuke)

What Is Sustain?

The Sustain step ensures that 5S is applied on an ongoing basis. It transforms your standardized 5S processes into regularly completed tasks.

Why Do You Need to Sustain?

Iterative 5S processes lock in your gains and ensure further and continued progress.

How to Implement Sustain

Once you’ve standardized, it’s time to continually act upon those standards. Sustaining the 5S methodology means focusing on maintaining the developed process with an eye toward continuous improvement or kaizen.

We recommend you:

- 1Create a schedule. Embed 5S practices as scheduled tasks (by role, shift, and frequency), encouraging your team to follow the established guidelines in each meeting.

- 2Set measurable goals. Determine key performance indicators (KPIs) that align effective implementation to critical measures like reduced defect rates or cycle times.

- 3Teach through demonstration. Appoint one or more employees as trainers (trainers instruct employees on how to conduct 5S tasks through demonstration). Showing employees what is expected of them will prepare them to conduct tasks on their own.

- 4Supervise to solo. After initial 5S training for employees, gently supervise while they continue to form habits. It is easy to make mistakes or fall off course, so patiently and helpfully offer corrections when needed.

- 5Audit 5S practices. Periodically audit your process through: inspections, employee meetings, and team reviews.

- 6Adapt as necessary. Establish an avenue for ongoing team feedback and encourage it, using either a monitored email address or a suggestion box on the plant floor. When giving or receiving feedback on tasks, see where changes can be made to make the tasks easier and more efficient. Standardized work is intended to be living documentation.

Key "Sustain" Advantages Include

- Sense of team empowerment and ownership

- Culture of ongoing learning, collaboration, and continuous improvement

- Enhanced focus on productivity, efficiency, effective communication, and quality output

- Expanded career pathways through specialized roles like 5S trainers

Industry Example: Precision Farming Equipment

The agriculture industry is evolving rapidly as advances like 5G and artificial intelligence transform equipment design. Therefore, production lines in this industry often need to run at an especially brisk pace, producing an evolving variety of complex components with many small parts. Adopting a standardized method for keeping the manufacturing space clean, uncluttered, and highly organized is imperative for efficiency, accuracy, and quality output.

Four Ways to Encourage 5S Buy-In and Participation

Are all the above concepts simple and clear-cut in meaning? Absolutely. Yet applying them consistently requires considerable discipline. Said another way: While the 5S process is straightforward and cost-effective to implement, it is not necessarily easy.

As with any new approach, sometimes a degree of change management is required to remind teams about the importance of your 5S adoption. Here are some suggestions for encouraging buy-in:

1. Develop a Timeline

Employees unfamiliar with 5S principles might need some time to absorb what it involves so they can understand new expectations. Give employees a running start by introducing the idea of 5S implementation a few weeks or months before you plan an official kickoff.

Create simple informational materials that focus on each step and its many advantages. Explain how 5S supports lean manufacturing initiatives. Emphasize that your goal is to help support employee engagement, advancement, and open communication. Also consider posting flyers and sharing handouts that remind your team about this important methodology.

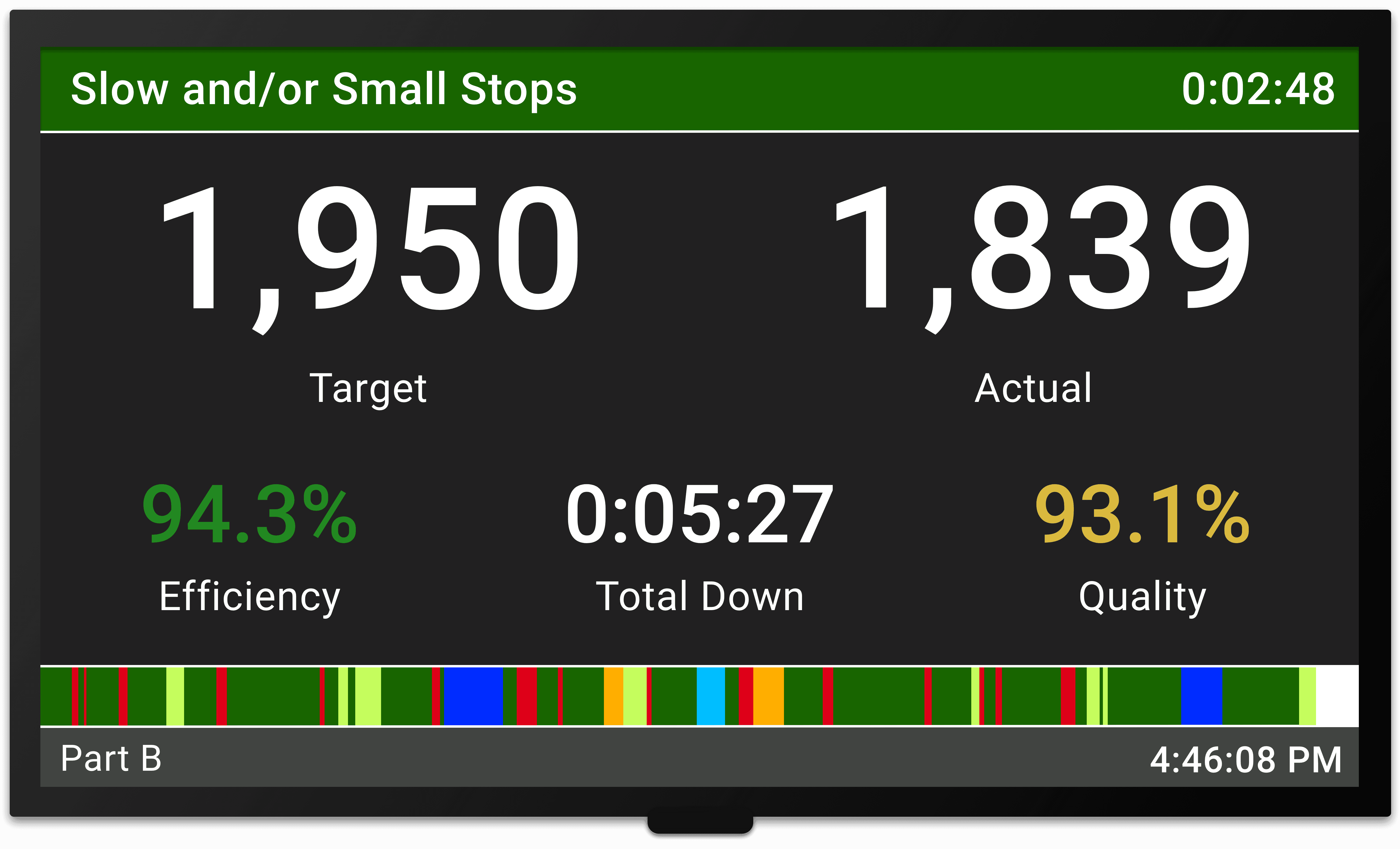

2. Tap into Technology

Why just stick with paper flyers or a whiteboard? Consider using a mobile app to share reminders, tip sheets, suggestion forms, and 5S training tools. Digital signage or production floor scoreboards are another great way to share highly visible reminders and encouraging messages that can significantly boost team awareness and engagement.

3. Demonstrate Top-Down Support

Ask your management team to be vocal about supporting your 5S initiative. Consider creating a short video message that can play on production line monitors, or distribute FAQs written by a respected leadership figure that emphasize the many benefits of adopting 5S. You could also make your suggestion box available well in advance. This helps to cement the idea that your 5S initiative is a positive step toward increased team ownership, collaboration, and engagement.

4. Announce Awards

Everyone likes to feel recognized for a job well done. Create quarterly 5S merit awards that encourage teammates to go the extra mile. Announce fun competitions with prizes that include traveling trophies, logo-adorned hats, framed certificates, special treats, or even just bragging rights. Consider utilizing the 5S trainer role as a “step up” opportunity for employees interested in coaching and educating others.

With its strong ties to lean manufacturing, 5S places the focus squarely on eliminating multiple kinds of waste (muda), enhancing agility, and decreasing the costs associated with inefficiency and extraneous movement. It's safe to say that 5S is a proven paradigm for enhancing organization, tidiness, employee engagement, and productivity on the manufacturing floor — and perhaps that’s the perfect segue to the “bonus S” of this time-honored approach. Read our article on "The Bonus S of 5S" to learn why safety is a critical benefit of any 5S implementation.

Manufacturing Evolved 5S, and 5S Shaped Lean Manufacturing

Propelled by burgeoning 5S principles, the resounding success of the TPS program helped Toyota — and then other Japanese automotive manufacturers — produce dependable and long-lasting, yet reasonably priced products. When the rest of the world began taking notice, however, there was initially some skepticism that these Japanese-inspired methods may not be readily transferable across cultures.

Toyota proved them wrong when they started building U.S.-based manufacturing plants and implementing this same system. That’s when 5S really came into its own, and it began laying the foundations for lean manufacturing across industries worldwide. Adherence to 5S standards is considered the foundation of Total Productive Maintenance (TPM) and an integral part of the Toyota Production System (TPS). 5S also creates a stable platform from which Kaizen activities can be launched.

The 5S methodology is a time-tested and highly regarded manufacturing framework that can help you substantially improve workplace organization, cleanliness, output quality, employee pride, and safety.

5S in Manufacturing Today

Today’s manufacturing processes often incorporate advanced and complex technology that supports agility, dependability, and efficiency. With so many literal and figurative “moving parts,” a high degree of organization has become imperative for smooth operations.

5S and the Toyota Production System (TPS)

5S originated as part of the Toyota Production System (TPS) and evolved into a key driver of lean manufacturing. Its objective is to improve overall productivity by eliminating waste (muda). Once 5S focus areas are introduced and implemented within a team, these principles collectively foster a more organized working environment that encourages employee ownership, boosts productivity, and reduces downtime.

5S: A Cornerstone of Lean Manufacturing

5S is firmly rooted in lean production principles, strongly aligned to the idea of comprehensive assessment that fuels gold-standard manufacturing metrics like OEE, and proven effective across industries around the world. Investing in your awareness of 5S, along with disciplined and dedicated implementation over time, can yield significant dividends that support your ongoing productivity, team collaboration, and success.

5S: Empowering Team for Continuous Improvement

5S is a low-investment, high-impact lean manufacturing tool that is predicated on people. It engages operators in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement.

Looking for additional ways to enhance collaboration, productivity, and worker morale? Keep reading to learn how you can excel in all these areas, and access free lean production tools below.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.