Safety: The Bonus “S” of 5S

Each 5S step contributes to the safety of your team, creating a cleaner and more organized workplace, as well as a sense of employee ownership over their space. Simply follow the 5S methodology, and safety will come naturally!

How Does 5S Improve Safety on the Plant Floor?

With its early roots in the philosophical foundations of the Toyota Production System (TPS) and its important role inspiring the concept of lean manufacturing, 5S strongly emphasizes organized productivity through its simple yet disciplined focus on five key principles:

- 1Sort/seiri: sorting through and eliminating that which is not truly needed

- 2Straighten/seiton: organizing what remains after sorting

- 3Shine/seisou: cleaning and inspecting the work area

- 4Standardize/seiketsu: creating standards that support a repeatable process

- 5Sustain/shitsuke: consistently applying these standards across work areas

Interestingly, there’s a highly advantageous side effect when enacting these five practices in a consistent, dedicated way — and coincidentally enough, it also begins with an “S.”

It’s what we like to call the “bonus S” of 5S: safety.

The Importance of Safety in the Workplace

Why is addressing this sixth “S” so crucial? Because ensuring worker well-being is not only essential to being a responsible employer, it’s also intrinsic to the ongoing success of your business. The Bureau of Labor Statistics found that in a single year, there are roughly 2.6 million reported non-fatal workplace injuries in the private sector — and manufacturing ranks highly on the list of industries with substantial non-fatal injury numbers.

Common causes of these injuries include falls, trips, slips, colliding with objects, and musculoskeletal stress. In fact, ErgoPlus reports that musculoskeletal issues alone are the leading cause of discomfort and disability in today’s U.S. workplaces. These ailments account for a whopping one-third of all worker compensation expenses, with total related employer costs estimated at over $50 billion annually.

Focusing on safety, as the old promotional saying goes, “makes dollars and sense.” The good news is that successfully implementing 5S as part of your ongoing manufacturing productivity protocols creates a positive, organized, cleaner, safer environment for your entire team. Decreasing clutter, dust and debris often leads to more space, an improved sense of employee well-being, and enhanced equipment functionality. Better yet, as your team focuses on continuous improvement or kaizen, these 5S benefits tend to accumulate over time. Let’s explore how each individual step in the 5S methodology contributes to a safer workplace.

How Each 5S Step Contributes to Safety

1. Sort

Sorting physically eliminates clutter from the plant floor, removing unnecessary items to create more space. This extra space comes in handy when housing important tools and materials, making them readily available when needed. Sorting also tends to result in:

- wider aisles,

- fewer tripping hazards, and

- more room to freely move about.

Similarly, on a smaller scale, decluttering drawers and shelves helps prevent accidental cuts or skin abrasions. After all, there’s less need to rummage around in messy spaces that might contain a jumble of sharp edges or metal corners.

2. Straighten

Straightening organizes each remaining item in a way that keeps it close at hand when it’s needed most. Operators waste less time rushing about and expending unnecessary energy looking for vital tools and materials. This can greatly reduce commotion on an already-busy plant floor, diminishing the risk of trips and collisions that could lead to falls or dangerous equipment malfunctions. Organized work areas also support healthy ergonomics. Workers who can move, stand, and sit comfortably experience less strain, fatigue, irregular postures, and related musculoskeletal issues.

3. Shine

Shining involves cleaning the workspace and maintaining equipment so it remains free of contaminants, dust, and grime. This helps prevent leaks and spills that could lead to hazardous slicks or puddles on the floor. It also optimizes the functionality of each tool, so operators don’t need to risk injury through misuse or excessive debris buildup. Additionally, there’s less chance of transferring greasy lubricant to hands that may need a sure and steady grip to complete critical tasks.

4. Standardize

Standardizing creates a clear and repeatable protocol that details step-by-step expectations, indicates which teammate is responsible for each specific duty, and indicates when those duties should be carried out. A standard operating procedure (SOP) helps ensure that important 5S tasks and inspections are undertaken on a regular basis.

Because detailed and established procedures help minimize team confusion, there’s less chance of missing an important sorting or cleaning step that could allow clutter, grime, or disorganization to recur.

This standardization results in:

- cleaner tools,

- clearer spaces,

- tidier workstations, and

- equipment that functions more consistently.

Employees remain more organized, so they experience less stress and confusion when working under tight deadlines. Overall, this creates a calmer and more orderly manufacturing space that supports safety and worker well-being.

5. Sustain

Sustaining means continuing to steadfastly embrace 5S initiatives over time, guided by standardized protocols that spell out expectations, roles, and responsibilities.

It also means encouraging ongoing team feedback that supports process improvement and the sharing of ideas. Employees who feel a sense of engagement and ownership over their workspaces often experience more pride and motivation related to their jobs.

Conversely, apathetic and disengaged employees are often detached and even irresponsible about their work habits, which can lead to careless mistakes that jeopardize safety or cause serious injuries.

Embrace the Safety Culture through 5S

5S is a powerful, foundational lean tool for bringing order to the factory floor. The 6th S, Safety, is an important added bonus that is naturally built into each of the 5S steps. While it is a lot of work to implement 5S, the process is worth the initial organizational work for the rewards in safety, production improvement, and employee motivation.

WHAT YOU SHOULD DO NEXT...

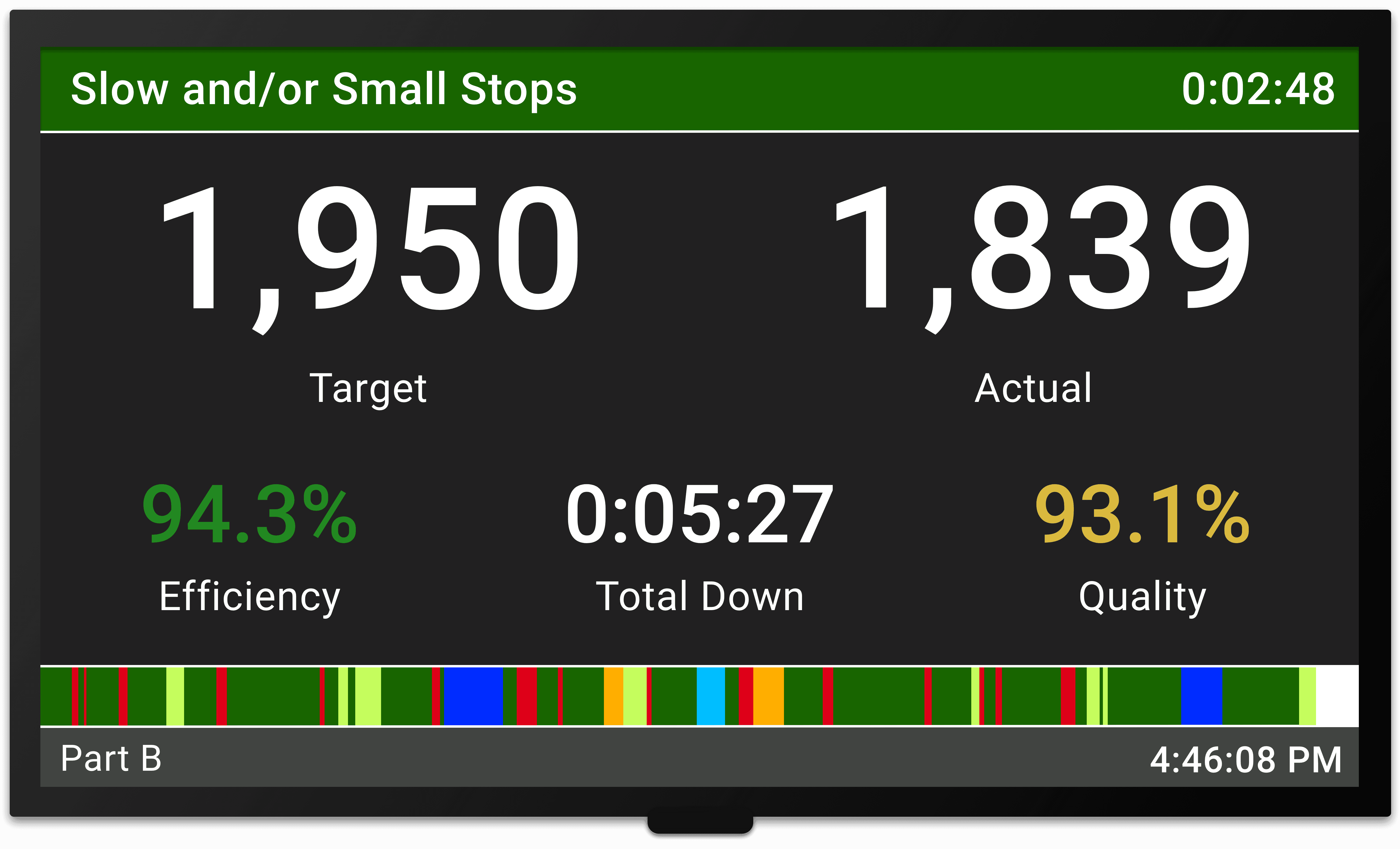

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.