The History of 5S and How It Helped Shape and Enhance Manufacturing

5S originated in Japan in conjunction with the Toyota Production System, and it quickly gained popularity worldwide as a simple yet effective method for eliminating waste from the manufacturing process.

The Origins of 5S in Lean Production

Sometimes, the best way to truly appreciate the importance of a topic is to explore its history. This is especially true when it comes to understanding and implementing 5S. While this five-step process for organizing a workplace and keeping it in optimal condition has its early roots in the Japanese automotive industry, the process was eventually embraced among Western manufacturers across market sectors. In fact, it was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing.

5S had its early beginnings with Toyota, which originally conceived a systematic approach to workplace organization that could enhance the success of its Toyota Production System (TPS). Two individuals at Toyota were particularly instrumental in the gradual development and refinement of this TPS methodology:

Taiichi Ohno and the Seven Wastes: Foundations of 5S

Taiichi Ohno was a Japanese industrial engineer who evolved from a shop floor supervisor to a senior Toyota executive, and he is widely considered to be the father of TPS. In addition to writing several books about this approach, including Toyota Production System: Beyond Large-Scale Production, Ohno also devised the concept of the seven wastes (muda in Japanese).

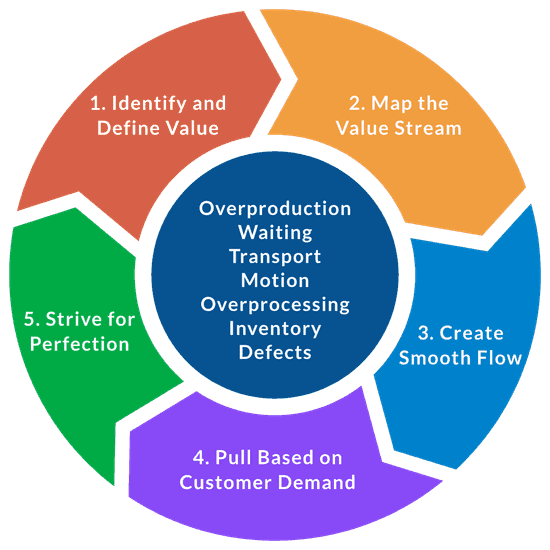

5S strives to eliminate these seven wastes, which include:

- 1Transport: product movement that isn’t required for processing

- 2Inventory: components, work in process materials, and finished product not being processed

- 3Motion: human or equipment movement beyond what is needed for processing

- 4Waiting: the state of being temporarily blocked from completing the next production step

- 5Overproduction: production that is ahead of existing customer demand

- 6Overprocessing: extraneous activity resulting from the poor condition of tools or materials

- 7Defects: extra effort needed to inspect or fix production errors

Shigeo Shingo and 5S

Shigeo Shingo was a highly respected industrial engineer and productivity lecturer who was invited by Taiichi Ohno to speak at Toyota in 1955. Over the years and in collaboration with Ohno, Shingo continued these on-site teachings to help train Toyota’s manufacturing engineers on implementing TPS.

Over the course of roughly two decades, Shingo used his extensive knowledge of motion analysis, time studies, and process optimization to advise the Toyota team — thereby helping to solidify, stabilize, and refine TPS methods.

Global Expansion of TPS and Its Evolution Into 5S

Fortified by the overwhelming success of TPS, Toyota’s competitive advantage continued to escalate. This led to increased global expansion, part of which involved the building of Toyota manufacturing facilities in the United States. By this time, other Japanese automotive manufacturers had already begun learning anything they could about TPS in an effort to keep pace. U.S.-based industry manufacturers now became extremely attuned to the TPS system as well, especially once Toyota began actively operating in their own backyard.

It was during this same general time frame that manufacturing productivity began to excel by leaps and bounds, largely due to a convergence of insights from industrialized nations around the world. A few prominent examples include:

- The manufacturing operations-related studies of Frederick W. Taylor at the Midvale Steel Company

- The groundbreaking inventions of automotive manufacturing visionaries like Henry Ford, Karl Benz, John Lambert, and Gottlieb Daimler

- The time-and-motion discoveries of industrial engineer Frank Bunker Gilbreth

It’s certainly fair to presume that these combined influences may have helped to evolve and refine TPS principles into the 5S model as we know it today. Yet, evolution of the TPS approach really accelerated when researchers at the Massachusetts Institute of Technology (MIT) published a book entitled, The Machine that Changed the World. These researchers, who had been meticulously studying Toyota’s organizational philosophies, began heralding the TPS system as an evolutionary manufacturing paradigm.

In fact, it was this book that first popularized the term “lean production”— a descriptor meant to distinguish Toyota’s pioneering system from standard mass production by emphasizing the goal of eliminating workplace waste and inefficiency.

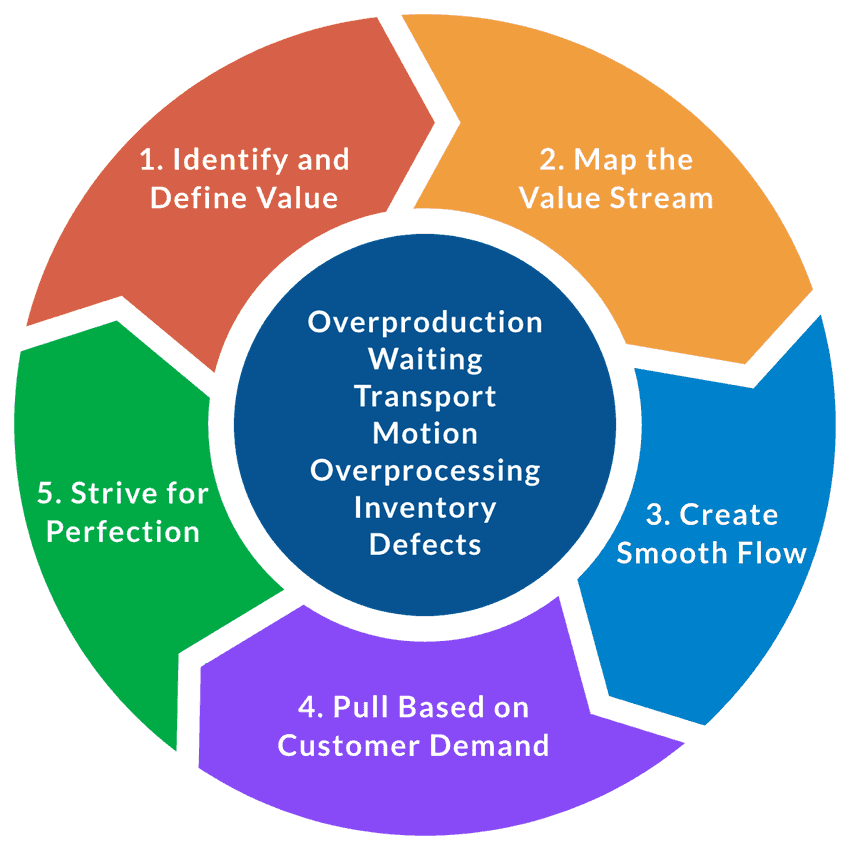

In Machine, the authors outlined a multi-step “recipe” for improving workplace efficiency:

- Defining value

- Mapping the value stream

- Creating flow

- Using a pull system to link production with customer demand

- Pursuing perfection

The Spread of 5S in the United States

As the idea of lean production quickly took hold in the public consciousness, global manufacturing leaders sought to capitalize on Toyota’s resounding success by adapting this new system to their own organizational needs. The resulting clamor for additional insights led to the first English-language book dedicated to explaining the 5S process by name. Published by Takashi Osada in 1991, the book was entitled, The 5S’s: Five Keys to a Total Quality Environment. It included a conceptual overview of key 5S principles, explaining management philosophies behind the approach.

Demand for this first book mushroomed so rapidly that another 5S book was published soon after. Author Hiroyuki Hirano created a straightforward, step-by-step 5S guide entitled, 5 Pillars of the Visual Workplace: The Sourcebook for 5S Implementation. In contrast to Osada’s offering, Pillars detailed core 5S tenets in a way that non-Japanese manufacturing organizations could readily grasp and incorporate.

Shigeo Shingo, for his part, continued to write prolifically about TPS-related process improvements throughout his lifetime. As the TPS process evolved and the concept of 5S solidified, Shingo also presented seminars that helped Western organizations clearly understand central philosophies behind the 5S paradigm. Consequently, he became equally renowned in the West and Japan for his 5S subject matter expertise. His name is also synonymous with the lean manufacturing process known as Single-Minute Exchange of Die (SMED). Shingo helped devise this concept to reduce manufacturing costs and cycle times.

The Continued Importance of 5S in Manufacturing

Decades later, 5S remains an effective methodology for maintaining order on the factory floor. Thanks to the influential teachings of lean trailblazers like Taiichi Ohno and Shigeo Shingo, 5S gained enough traction worldwide to become a core lean principle that is still applicable even as factory technology rapidly advances.

WHAT YOU SHOULD DO NEXT...

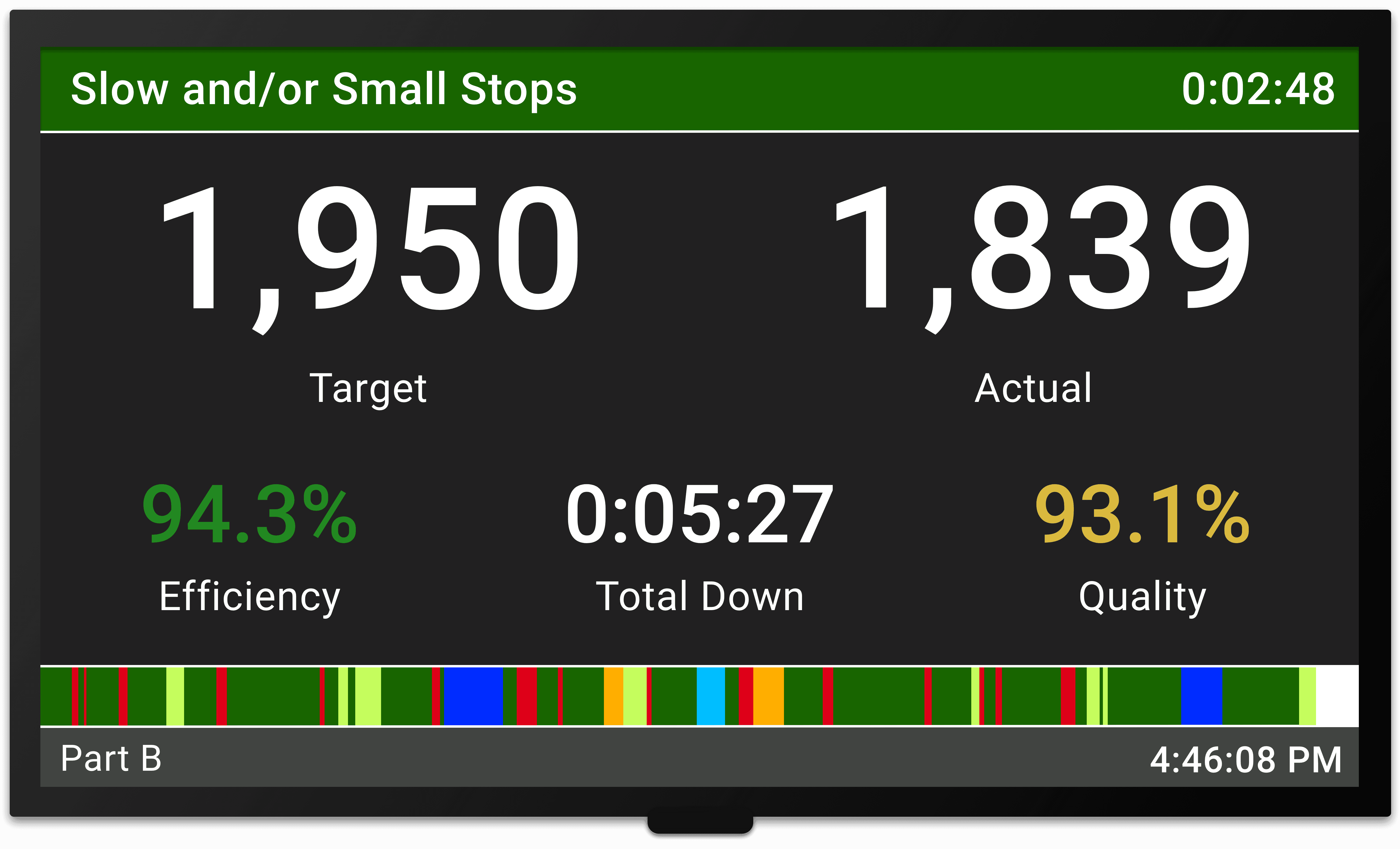

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.