5 Key Reasons Why 5S Is So Essential to Manufacturing

Implementing 5S provides a myriad of benefits beyond the direct result of a clean and organized factory floor including a reduction in waste, a foundation for additional lean techniques, an engaged plant floor team, bolstered TPM and kaizen initiatives, and a reduction of risk in the workplace.

5S Influence In Manufacturing

While 5S was first developed in the context of the automotive industry, it is now widely considered a critical step for any lean manufacturing program in any industry. Today, manufacturing organizations worldwide continue to embrace 5S methods. It’s widely agreed that this productivity-focused paradigm:

- Is easy to understand and inexpensive to implement

- Improves activity flow

- Keeps equipment cleaner and more accessible

- Supports a more productive work environment

- Encourages operators to “own” their workspaces

- Instills a disciplined commitment to quality and continuous improvement

5S is straightforward to comprehend and adaptable across industries, yet wide-ranging in its scope and impact. Its five sequential focus areas (sort/seiri, straighten/seiton, shine/seisou, standardize/seiketsu, sustain/shitsuke) aim to clear clutter, tidy workspaces, and enhance ongoing organization.

Here are five key reasons why 5S remains such an influential force across today’s manufacturing landscape:

1. Emphasis on waste reduction (muda)

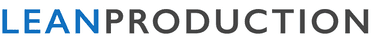

Saying that 5S helps manufacturing teams to reduce muda or waste is something of an understatement. 5S is uniquely effective because it helps teams to eliminate the seven types of waste from the Toyota Production System: transport, inventory, motion, waiting, overproduction, overprocessing, and defects. Thus, examples of real-life waste reduction are almost endless — from a restaurant supply manufacturer reducing its processing times to a plastic container fabricator decreasing its scrap. By using the 5S methodology, operators are encouraged to improve their overall work environment.

2. Foundation for lean production

5S serves as the foundation for lean manufacturing practices. It incorporates other lean techniques such as Just-In-Time production, value stream mapping, and continuous flow manufacturing. 5S strongly underscores and supports a variety of lean production principles, tools, philosophies, and metrics, including:

- 1Just-in-time production: an inventory strategy that seeks to manufacture items according to customer demand, aligning the entire material flow to minimize extraneous effort

- 2Value stream mapping: a practice that monitors material progress across every step of the production process, identifying blocks and bottlenecks in a way that creates a more organized, streamlined approach

- 3Continuous flow manufacturing: a production method that minimizes waiting time and disruption by ensuring that items move smoothly from one manufacturing process to the next

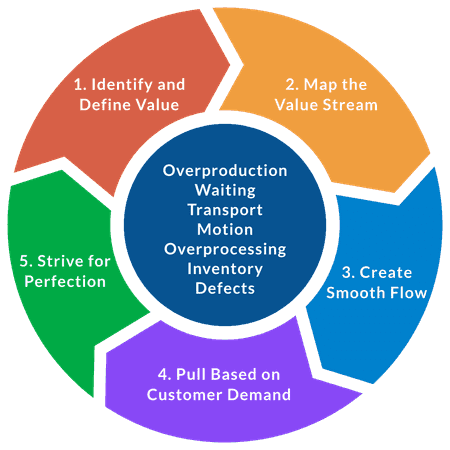

- 4Overall equipment effectiveness (OEE): a metric-driven approach to productivity that evaluates factors such as equipment availability, process performance, and output quality to help organizations objectively assess the overall effectiveness of their processes — with a systematic focus on uncovering opportunities for improvement that strongly echoes 5S objectives.

As previously discussed, the evolution of the TPS process into a growing emphasis on 5S brought the idea of lean manufacturing to the forefront – thereby ushering in a revolutionary new era of productivity and cost-efficiency.

3. Emphasis on employee engagement

Toyota’s original TPS paradigm encouraged worker input regarding the way daily manufacturing operations were carried out. Similarly, 5S seeks to empower employees by giving them a sense of ownership over their production spaces and work processes.

The element of straighten or seiton, for example, encourages workers to organize their areas in ways that support time efficiency and an economy of movement. The element of shine or seisou inspires employees to regularly clean their workspaces, helping them take pride in the manufacturing tasks they support.

The bottom line - 5S is a low-investment, high-impact lean manufacturing tool that is predicated on people. It engages operators in ‘owning’ their workspace and helps to instill a culture of quality, productivity, and improvement.

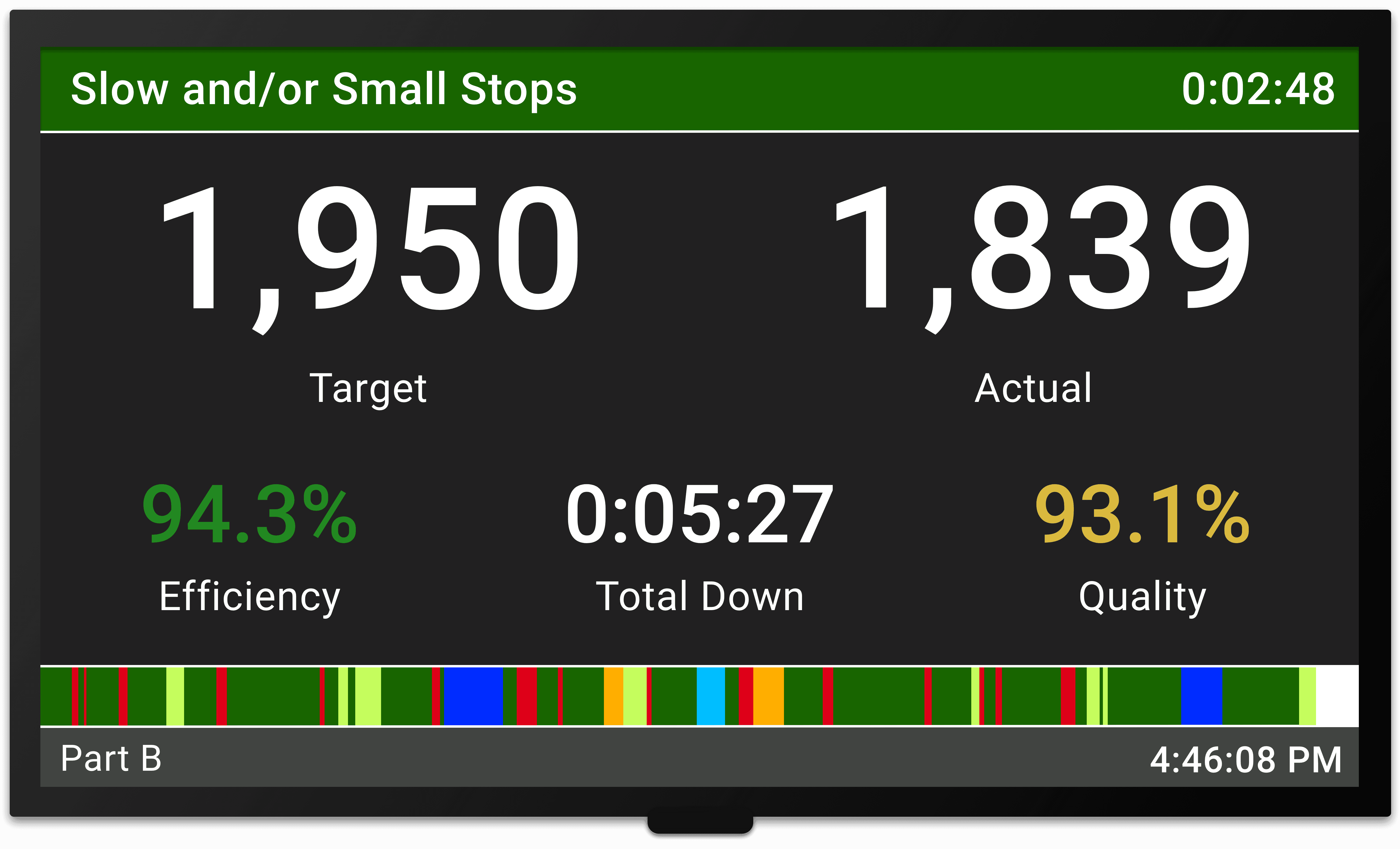

4. Alignment with Total Productive Maintenance (TPM) and Kaizen principles

5S prioritizes ongoing equipment inspection and maintenance, reinforced by the creation of documented standards. This helps reduce downtime and enhance output quality, while encouraging worker engagement and ownership.

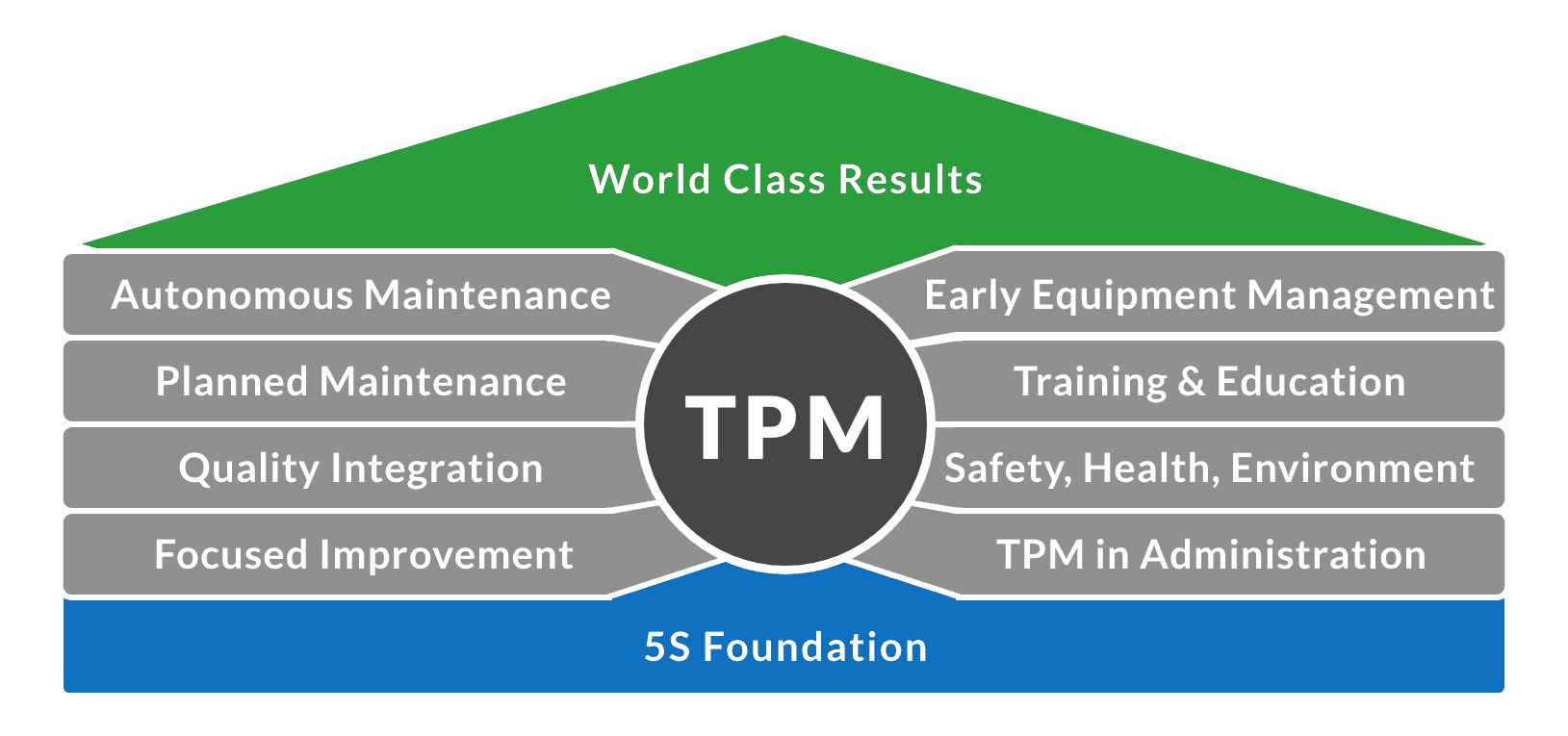

Adherence to 5S standards is considered the foundation of Total Productive Maintenance (TPM) and an integral part of the Toyota Production System (TPS). Total Productive Maintenance (TPM) is a comprehensive approach to equipment upkeep that aims to achieve a “perfect” production state with zero breakdowns, defects, or accidents. Unlike conventional methods, which emphasize periodic intervention from a maintenance team, TPM asks all employees to take an active and ongoing role in maintaining equipment operation. This strongly aligns with 5S.

It’s also been noted that 5S similarly supports kaizen — a Japanese term referring to continuous improvement on the manufacturing floor. In particular, the tenets of standardize/seiketsu and sustain/shitsuke demand a level of discipline that fosters ever-increasing levels of stability, predictability, and output quality.

5. Risk reduction

We’ve already seen how 5S encompasses the consistent application of five key workspace organization principles beginning with the letter “S.” Yet there’s a critical sixth term that should not be overlooked. Keeping work areas in order offers the valuable bonus benefit of safety. Consistently removing clutter, debris, and grime supports added space and improved equipment operation – which, in turn, can greatly reduce the risk of accidents and injuries.

Employees with greater freedom to move around also reduce their risk of musculoskeletal or repetitive motion injuries associated with cramped areas, awkward positioning, or poor posture. Personal days and worker’s compensation claims can add up quickly, so keeping work areas in order offers the valuable bonus S of 5S: safety.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.