Kaizen

What is Kaizen?

Kaizen is a strategy where employees at all levels of a company work together proactively to achieve regular, incremental improvements to the manufacturing process. In a sense, it combines the collective talents within a company to create a powerful engine for improvement. Kaizen is also referred to as Continuous Improvement.

The Dual Nature of the Kaizen System

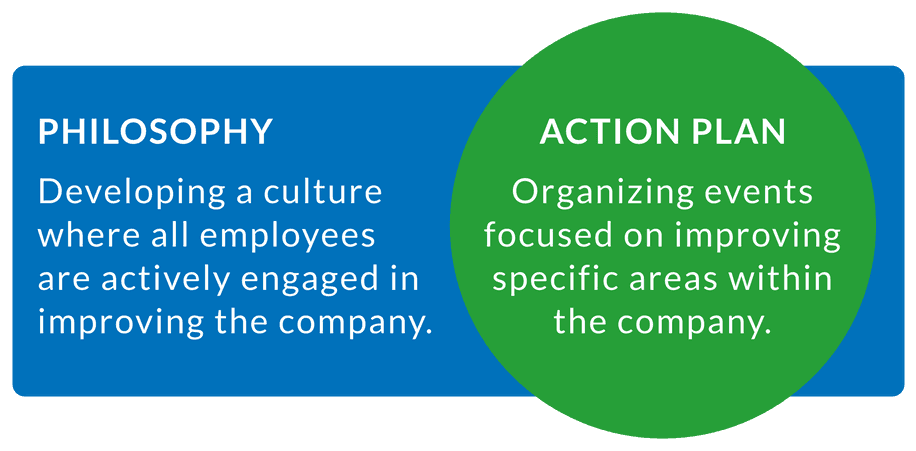

Kaizen is part action plan and part philosophy.

- As an action plan, Kaizen is about organizing events focused on improving specific areas within the company. These events involve teams of employees at all levels, with an especially strong emphasis on involving plant floor employees.

- As a philosophy, Kaizen is about building a culture where all employees are actively engaged in suggesting and implementing improvements to the company. In truly lean companies, it becomes a natural way of thinking for both managers and plant floor employees.

Kaizen works hand-in-hand with Standardized Work. Standardized Work captures the current best practices for a process, and Kaizen aims to find improvements for those processes. Note the emphasis on current; Standardized Work is living documentation (it continually evolves through Kaizen).

Kaizen Events

A typical Kaizen event has a process that goes something like this:

- Set goals and provide any necessary background.

- Review the current state and develop a plan for improvements.

- Implement improvements.

- Review and fix what doesn’t work.

- Report results and determine any follow-up items.

This type of Kaizen process cycle is frequently referred to as PDCA (Plan, Do, Check, and Act). PDCA brings a scientific approach to making improvements:

- Plan: develop a hypothesis

- Do: run experiment

- Check: evaluate results

- Act: refine your experiment; then start a new cycle

The Kaizen Philosophy

Interestingly, Kaizen as an action plan is exactly what develops Kaizen as a philosophy. When Kaizen is applied as an action plan through a consistent and sustained program of successful Kaizen events, it teaches employees to think differently about their work. In other words, consistently applying Kaizen as an action plan creates tremendous long-term value by developing the culture that is needed for truly effective continuous improvement.

WHAT YOU SHOULD DO NEXT...

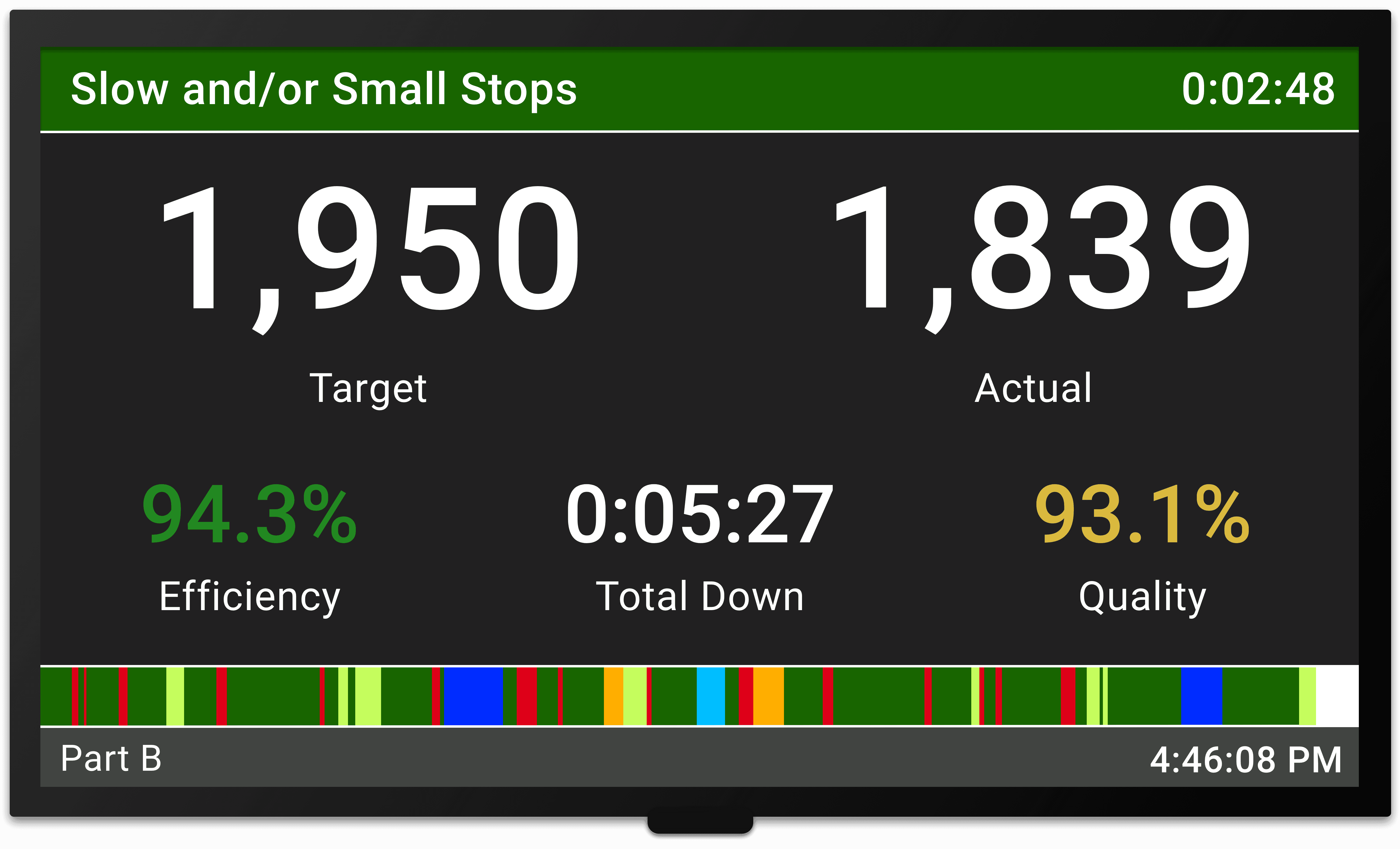

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.